201, 304, 347H, S32205 Stainless Steel Welded Pipe/ ERW

product features

1. Chemical analysis: Conduct chemical analysis of the chemical components of the material, and the chemical ingredients meet the standards.

2, Air pressure. Hydrostatic test For the hydraulic test, the specified pressure value is not less than 5 seconds, and no leakage is kept. The hydraulic pressure test of conventional supply is 2.45MPa. The atmospheric pressure test is P=0.5MPAa.

3. Corrosion test: the industrial corrosion resistant steel pipes shall be tested for their corrosion resistance according to the standards or the corrosion methods agreed by both parties, without intercrystalline corrosion tendency.

4, process performance inspection: flattening test. tension test. blow-test. flaring test. hardness test. metallographic test. bend test. Nondestructive testing (including eddy current testing. X-ray and ultrasonic detection).

According to the use, it can be divided into oil well pipe (casing, oil pipe and drill pipe, etc.), pipeline pipe, boiler pipe, mechanical structure pipe, hydraulic pillar pipe, gas cylinder pipe, geological pipe, chemical pipe (high pressure fertilizer pipe, petroleum cracking pipe) and ship pipe, etc.

Production process of stainless steel welding pipe

Raw materials- -strip- -welding pipe- – -repair end- -polishing- -inspection (printing) – -packaging- -shipment (warehousing) (decorative welding pipe).

Raw materials- -strip- -welding pipe- -heat treatment- -correction- -straightening- – -repair end- -pickling- -water pressure test- -inspection (printing) -packaging- -shipment (warehouse) (welding pipe industrial distribution pipe).

Product Detail

|

Steel Grade: |

304,304L,309S,310S,316,316L,317,317L,321,347,347H,304N,316L, 316N,201,202,S32205 |

|

Standard: |

ASME/ASTM/DIN/EN/JIS |

|

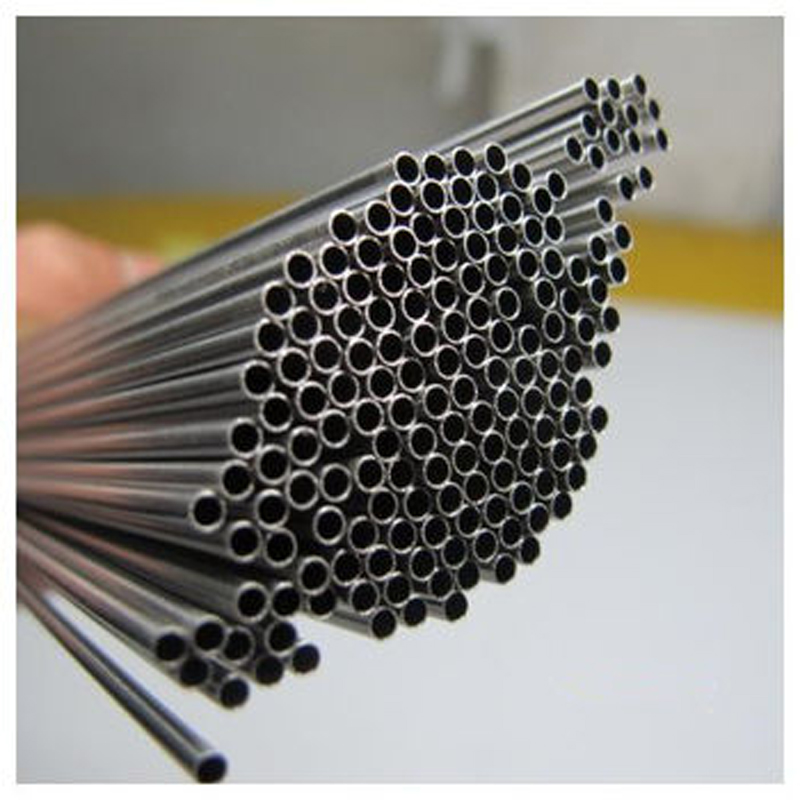

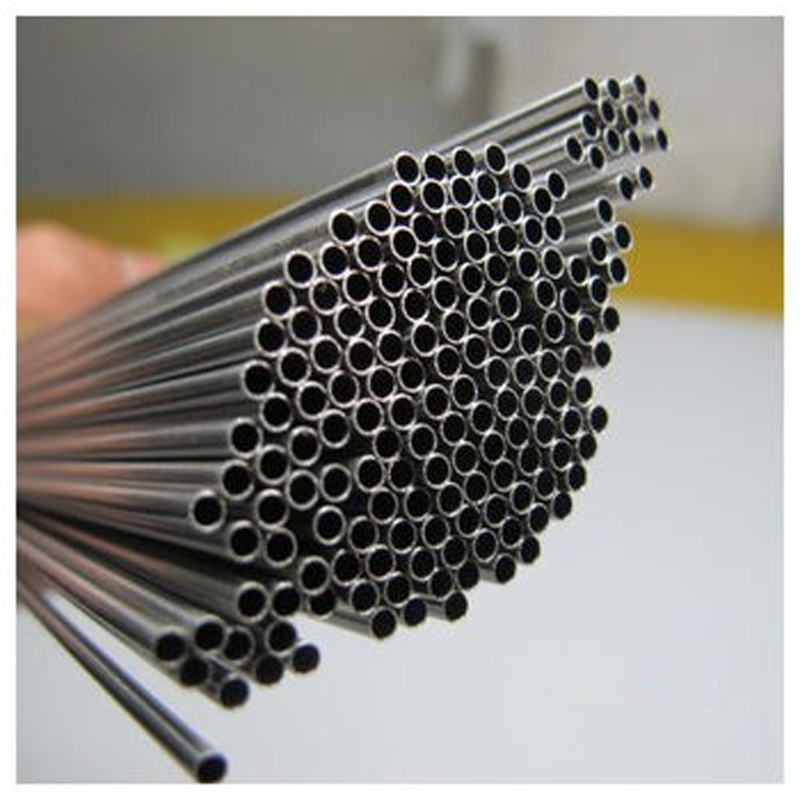

Specification: |

Outdiameter 10~508mm |

|

Wt: |

1.0-30mm,or according to customer’s special request |

|

Length: |

2-20meters,or according to customer’s special request |

|

Package: |

Export Standard Package |

|

Typies of tube: |

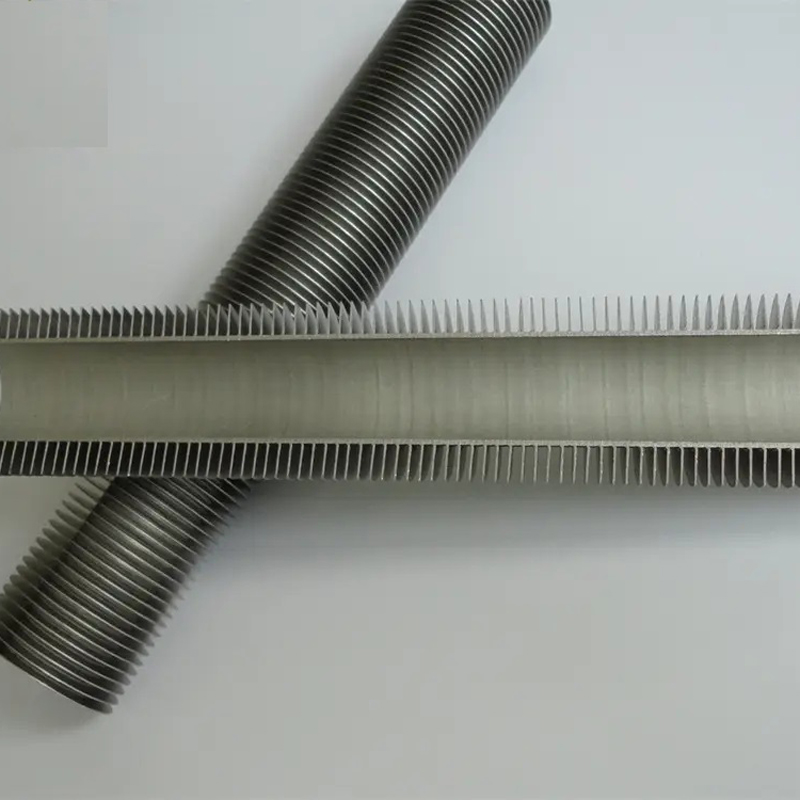

Stainless Seamless Steel Tube,Boiler tube,precision tube,mechanical tubing,cylinder tube,line pipes,etc |

|

Mill MTC: |

Supplied before shipment |

|

Inspection: |

The Third Party inspection can be accepted,SGS,BV,TUV |

|

Mount port: |

Any port in China |

|

Trade Term: |

FOB,CIF,CFR,EXW,etc. |

|

Price Term: |

TT or LC at sight |

|

Our services: |

We can customized according to customer’s requriement or drawing ,packaging according to customers’ request |

Factory Show