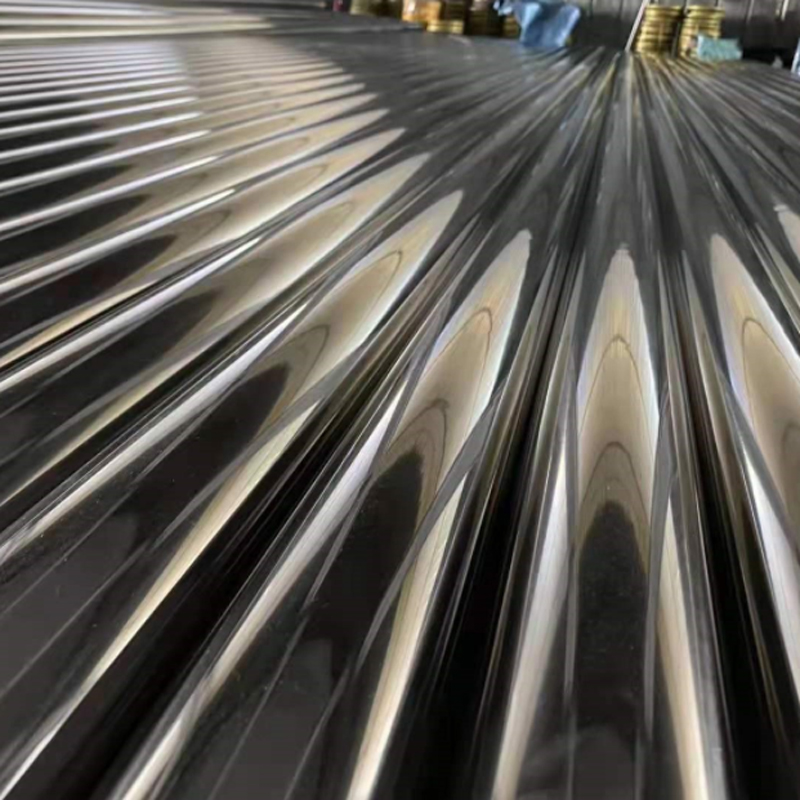

304, 310S, 316L Stainless Seamless Steel Pipe

Manufacturing process of stainless steel seamless pipe

1. Hot rolling (extruded seamless steel pipe): round pipe billet heating perforation three roll inclined rolling, continuous rolling or extruded tube diameter (or reduced diameter reduction) cooling straightening hydrostatic test (or flaw test) mark for storage

2. Cold pull (rolled) seamless steel pipe: round pipe billet heating perforated head, annealed acid, washing and coated oil (copper plating), multi-channel cold pull (cold rolled) billet pipe heat treatment straightening hydraulic test (flaw detection) mark into the storage.

According to different production methods can be divided into hot rolling pipe, cold rolling pipe, cold drawing pipe, extrusion pipe, etc.

1.1 Hot rolled stainless steel seamless pipe is generally produced on automatic rolling unit. The solid tube blank is checked and cleared from the surface defects, cut into the required length, centering on the tube blank perforation end surface, and then sent to the heating furnace for heating, perforated on the punch. In the perforation constantly rotating and forward at the same time, under the action of the roll and the head, the tube billet gradually formed a cavity, called the wool tube. Then sent to the automatic pipe mill for further rolling. Finally, the whole wall thickness of the whole machine, the diameter of the diameter machine, to meet the specification requirements. It is an advanced method to produce hot rolled seamless steel pipe by continuous rolling unit.

1.2. In order to obtain a smaller size and better quality seamless pipes, cold rolling, cold drawing or two combination methods must be adopted. Cold rolling is usually performed on a two-roll rolling mill, and the steel pipe is rolled in an annular hole type composed of variable section round hole groove and motionless conical top. Cold drawing is usually performed on a single chain or double chain cold pull machine from 0.5 to 100 T.

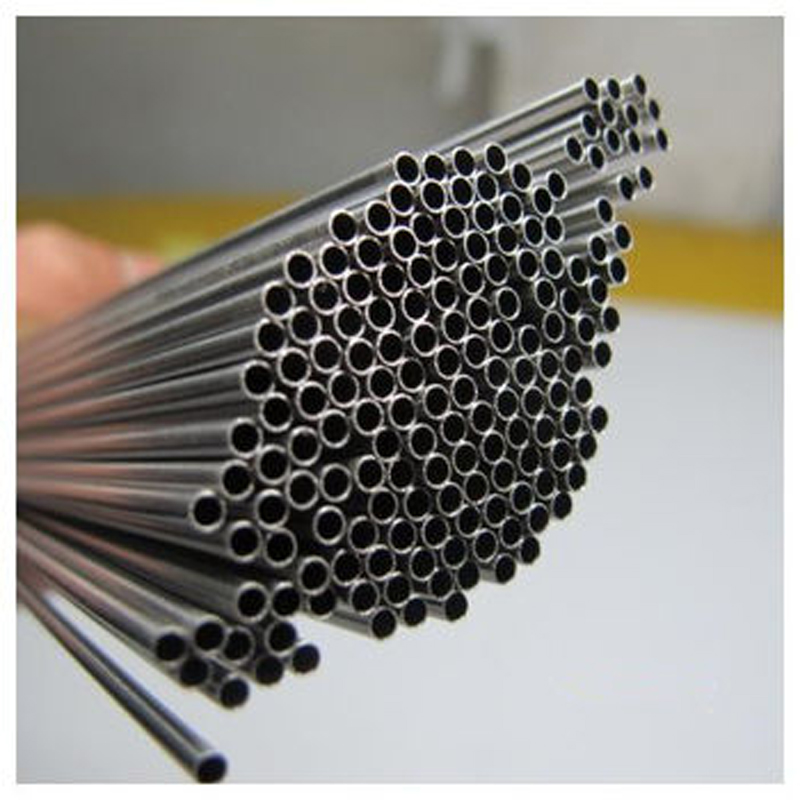

1.3. The extrusion method places the heated tube blank in a closed extrusion cylinder, and the perforating rod and the extrusion rod move together, so that the extruded parts are squeezed out from the smaller mold hole. This method can produce steel pipes with small diameter.

Product Detail

|

Steel Grade: |

304,304L,309S,310S,316,316L,317,317L,321,347,347H,304N,316L, 316N,201,202,S32205 |

|

Standard: |

ASME/ASTM/DIN/EN/JIS |

|

Specification: |

Outdiameter 10~508mm |

|

Wt: |

1.0-30mm,or according to customer’s special request |

|

Length: |

2-20meters,or according to customer’s special request |

|

Package: |

Export Standard Package |

|

Typies of tube: |

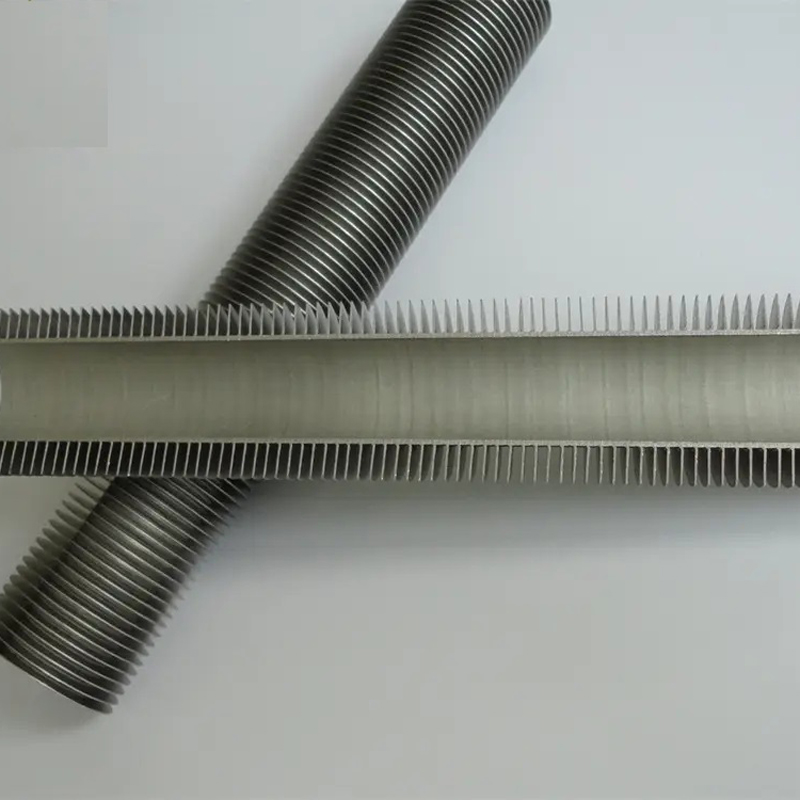

Stainless Seamless Steel Tube,Boiler tube,precision tube,mechanical tubing,cylinder tube,line pipes,etc |

|

Mill MTC: |

Supplied before shipment |

|

Inspection: |

The Third Party inspection can be accepted,SGS,BV,TUV |

|

Mount port: |

Any port in China |

|

Trade Term: |

FOB,CIF,CFR,EXW,etc. |

|

Price Term: |

TT or LC at sight |

|

Our services: |

We can customized according to customer’s requriement or drawing ,packaging according to customers’ request |

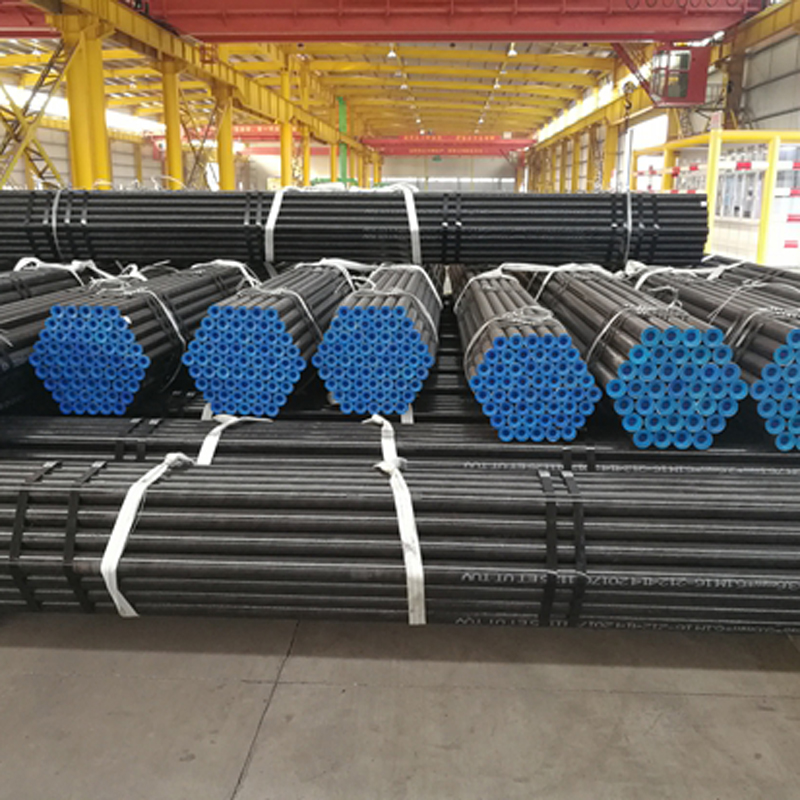

Factory Show