304, 316, 347H, S32205 Stainless Steel Welded Pipe/ERW

Product presentation

316L stainless steel welded pipe is a basic pipe, so it also has a lot of hard and necessary indicators, including many aspects, the following we want to talk about the hardness index of 16L stainless steel welded pipe. According to the test method and application range, hardness can be divided into brinell hardness, Rocell hardness, Vers hardness, Shore hardness, microhardness and high temperature hardness. For the pipe commonly used cloth, Roche, Vickers hardness three.

Brinell hardness (HB uses a steel ball or cemented alloy ball with a certain diameter to press the sample surface with the defined test force (F), remove the test force after the retention time, measure the indentation diameter (L) of the surface of the test sample is the test force divided by the indentation spherical surface area. Repressed by HBS (steel ball), the unit is N/mm2 (MPa calculation formula is the formula: F- -test force of 316L stainless steel welded pipe surface, N, D- -steel ball diameter, mmd- -indentation uniform diameter, mm. Brinell hardness determination is correct and reliable, but generally HBS is only used for metal materials below 450 N/mm2 (MPa), for hard steel or thin 316L stainless steel welded pipe. In the 316L stainless steel welded pipe scale, the Brinell hardness is the most widely used, often with the indentation diameter d to indicate the hardness of the material, which is both intuitive and convenient.

Production process of stainless steel welding pipe

Raw materials- -strip- -welding pipe- – -repair end- -polishing- -inspection (printing) – -packaging- -shipment (warehousing) (decorative welding pipe).

Raw materials- -strip- -welding pipe- -heat treatment- -correction- -straightening- – -repair end- -pickling- -water pressure test- -inspection (printing) -packaging- -shipment (warehouse) (welding pipe industrial distribution pipe).

Product Detail

|

Steel Grade: |

304,304L,309S,310S,316,316L,317,317L,321,347,347H,304N,316L, 316N,201,202,S32205 |

|

Standard: |

ASME/ASTM/DIN/EN/JIS |

|

Specification: |

Outdiameter 10~508mm |

|

Wt: |

1.0-30mm,or according to customer’s special request |

|

Length: |

2-20meters,or according to customer’s special request |

|

Package: |

Export Standard Package |

|

Typies of tube: |

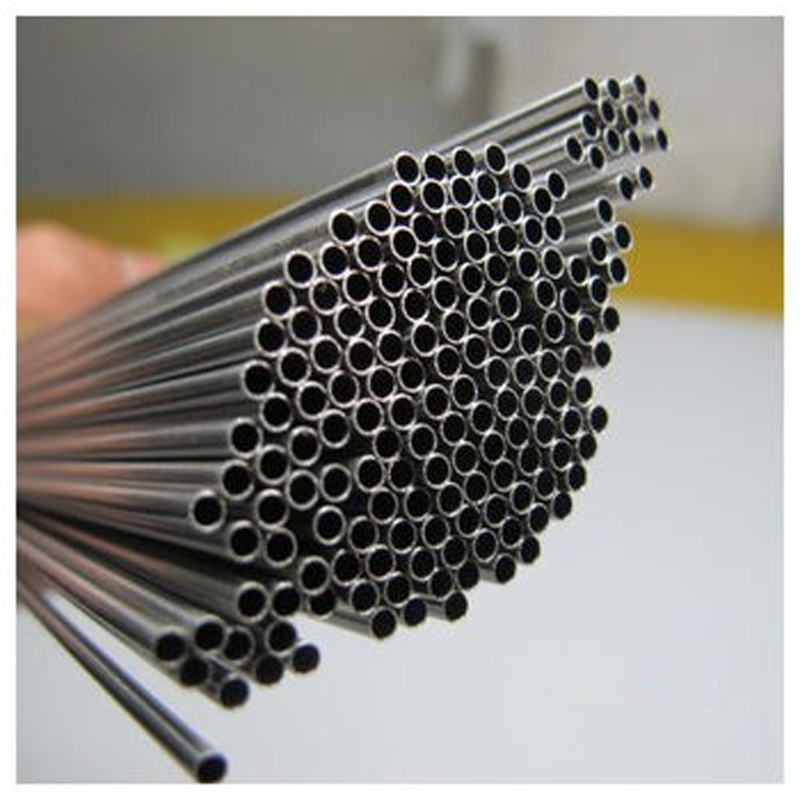

Stainless Seamless Steel Tube,Boiler tube,precision tube,mechanical tubing,cylinder tube,line pipes,etc |

|

Mill MTC: |

Supplied before shipment |

|

Inspection: |

The Third Party inspection can be accepted,SGS,BV,TUV |

|

Mount port: |

Any port in China |

|

Trade Term: |

FOB,CIF,CFR,EXW,etc. |

|

Price Term: |

TT or LC at sight |

|

Our services: |

We can customized according to customer’s requriement or drawing ,packaging according to customers’ request |

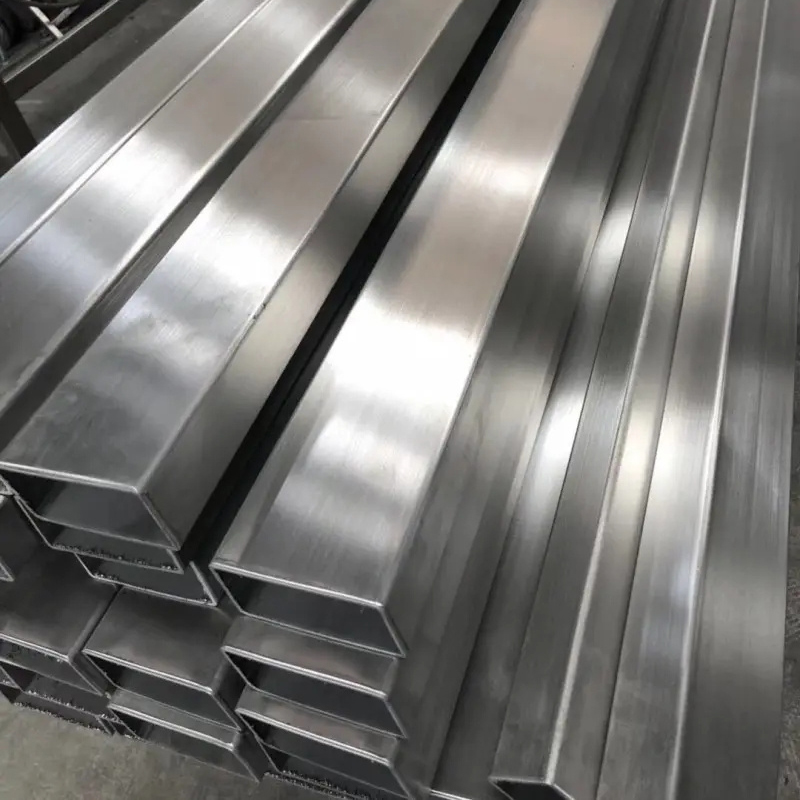

Factory Show