A106B A210A1 A210C / Carbon Steel Seamless Pipe

Quality inspection method of seamless steel pipe

1. Chemical composition analysis: chemical analysis method, instrument analysis (infrared C-S instrument, direct reading spectrometer, zcP, etc.).

① Infrared C-S instrument: analysis of ferroalloy, steelmaking raw materials, C, S elements in steel.

② Direct reading spectrometer: C, Si, Mn, P, S, Cr, Mo, Ni, Cn, A1, W, V, Ti, B, Nb, As, Sn, Sb, Pb, Bi in the block samples

③ N- -0 instrument: gas content analysis N and O.

2. Surface quality inspection of steel pipe: 100%

① Manual visual inspection: lighting conditions, standards, experience, identification, steel pipe rotation.

② NDT inspection:

A. Ultrasonic detection UT:

B. ET: (electromagnetic induction)

C. MT and leakage detection:

Magnetic flaw detection, suitable for the detection of surface and near-surface defects of ferromagnetic materials.

D. Electromagnetic ultrasonic flaw detection:

No coupling medium is needed, which can be applied to high temperature and high speed, rough and dry steel pipe surface flaw detection.

E. liquid penetrating test:

Fluorescence, coloring, and detecting of steel pipe surface defects.

3. Physical and chemical performance inspection of steel pipe:

① Tensile test: measure the stress and deformation, determine the strength of the material (YS, TS) and plastic index (A, Z)

Longitudinal, transverse section, arc, circular (¢ 10, ¢ 12.5)

Small diameter, thin wall, large diameter, thick wall calibration distance.

② Impact test: CVN, notch C, V, work J value J / cm2

Standard sample 101055 (mm) Non-standard sample 55 5 (mm)

③ Hardness test: Brinell hardness HB, Rockell hardness HRC, Vickers hardness HV, etc

④ Hydraulic test: test pressure, stabilization time, p=2S δ / D

4. Process performance inspection of steel pipe:

① Flat test: round sample C-shaped sample (S / D & gt; 0.15) H= (1 + 2) S / (+ S / D)

L=40~100mm per unit length deformation coefficient =0.07~0.08

② Pull test: L=15mm without crack is qualified

③ Expansion and curling test: the top taper is 30°, 40° and 60°

④ Bending test: can replace the flattening test (for large diameter pipe).

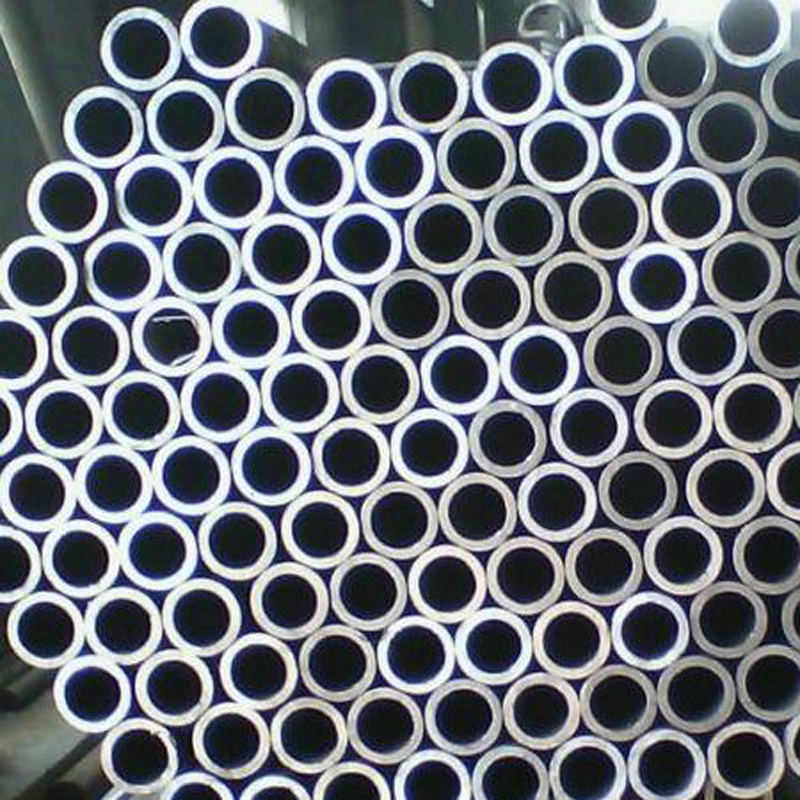

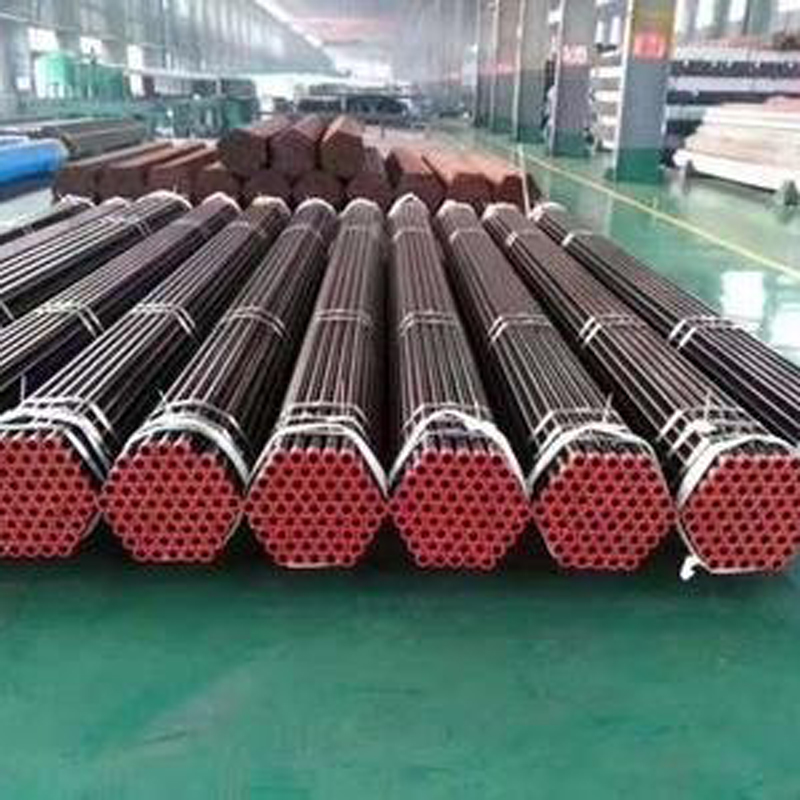

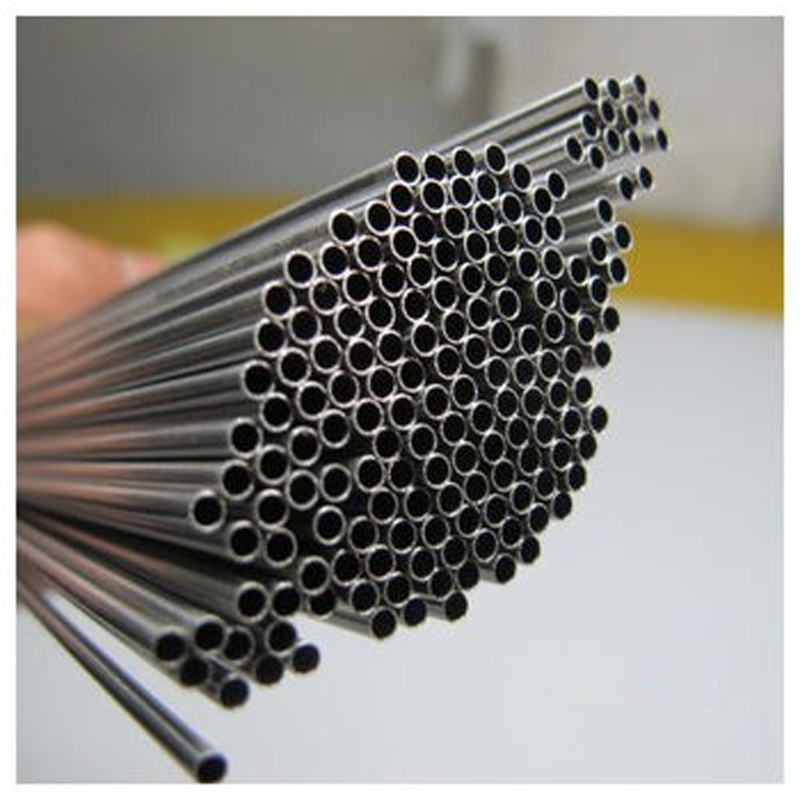

Product Detail

|

Steel Grade: |

106B,210A1,210C,P9,P11,T1,T11,T2,T5,T12,T22,T23,T91,T92,P235GH,13CrMo4-5,15Mo3,10CrMo9-10, ST35.8,ST45.8,STB340,STBA 12-2,API5L,5CT |

|

Standard: |

ASME/ASTM SA/A53/513/106/209/210/213/335/178/179/519 ASME/ASTM SA/A213,A312,A269,A778,A789, DIN 17456, DIN17457,DIN 17459,DIN17175,EN10216,BS3605,BS3059 |

|

Specification: |

Outdiameter 10~508mm |

|

Wt: |

1.0-30mm,or according to customer’s special request |

|

Length: |

2-20meters,or according to customer’s special request |

|

Package: |

Export Standard Package |

|

Typies of tube: |

Boiler tube,precision tube,mechanical tubing,cylinder tube,line pipes,etc |

|

Mill MTC: |

Supplied before shipment |

|

Inspection: |

The Third Party inspection can be accepted,SGS,BV,TUV |

|

Mount port: |

Any port in China |

|

Trade Term: |

FOB,CIF,CFR,EXW,etc. |

|

Price Term: |

TT or LC at sight |

|

Our services: |

We can customized according to customer’s requriement or drawing ,packaging according to customers’ request |

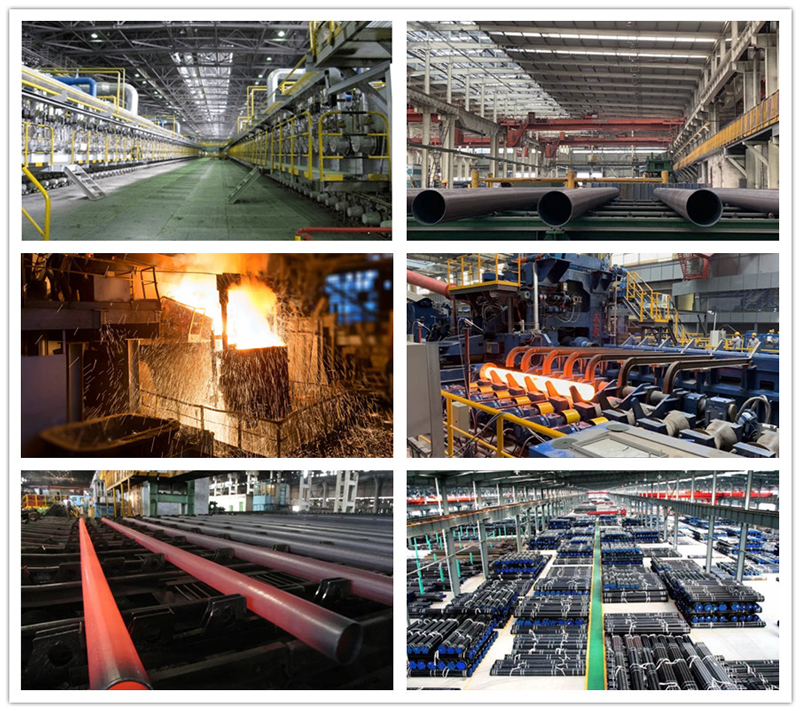

Factory Show