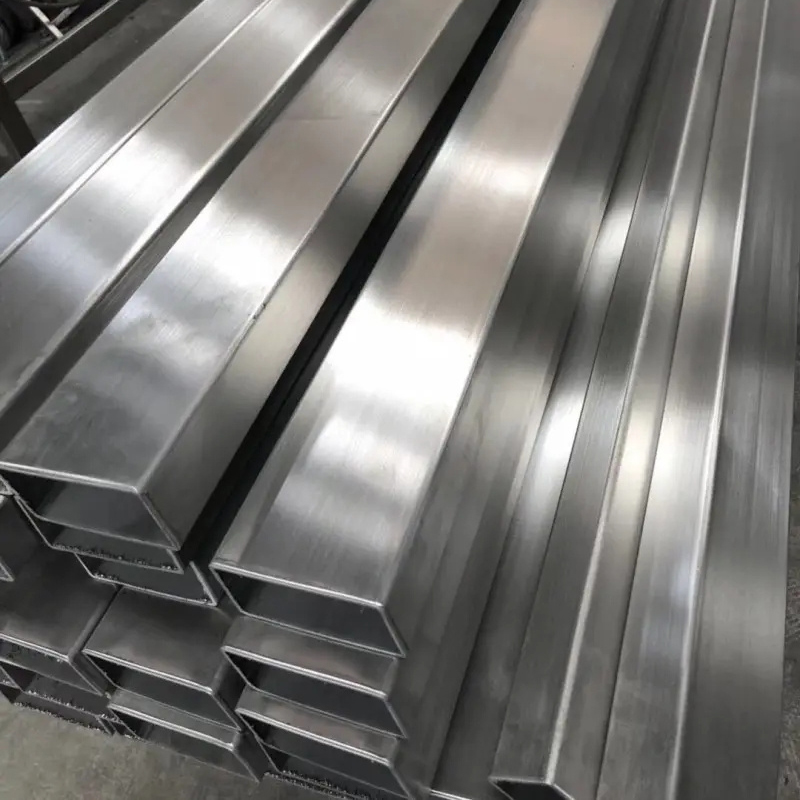

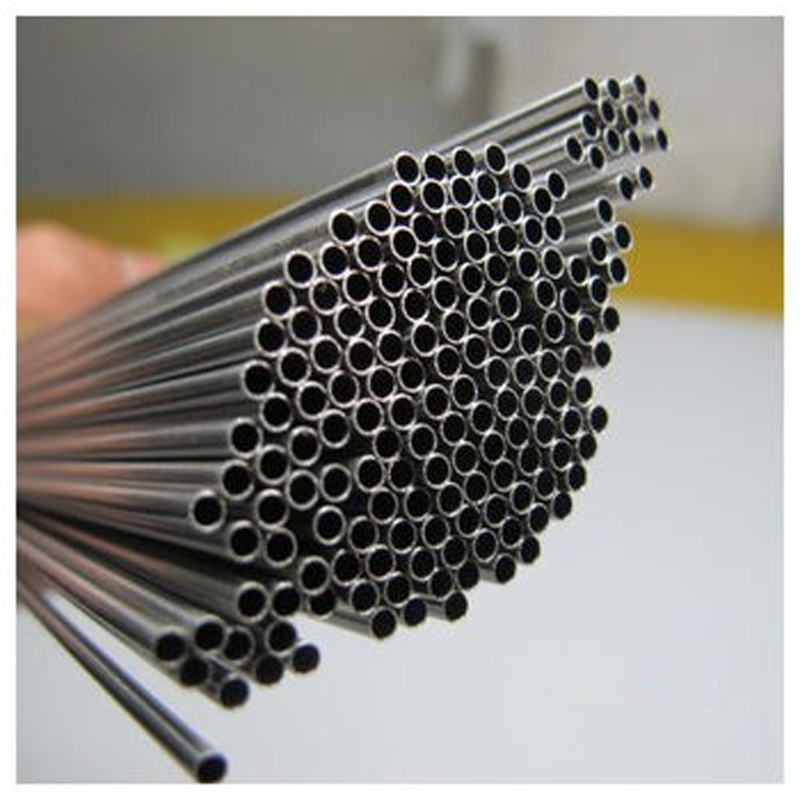

A214 A178 A423 A53 Straight Welded Pipe, ERW, Spiral Welded Pipe

fabrication process

The manufacturing process of stainless steel welding pipe mainly includes cold drawing, cold rolling, cold drawing, hot rolling and welding process. First, the stainless steel belt after cold drawing or cold rolling process, its thickness, width is adjusted. Then, after the cold drawing process, the stainless steel belt is pulled into a pipe type. Finally, the hot rolling or welding process has the required physical and chemical properties.

Advantages and characteristics

1. High temperature resistance: stainless steel welded pipe has good high temperature resistance, can work for a long time in a high temperature environment, not easy to deform or break.

2. Corrosion resistance: stainless steel welded pipe has a strong corrosion resistance, can resist the erosion of acid, alkali, salt and other corrosion media, has a long service life.

3. Strong compressive ability: because the stainless steel welded pipe adopts the welding process, the pipe wall is uniform, the internal and external pressure can withstand, and has a high compressive ability.

4. High surface finish: stainless steel welded pipe surface is polished, with a high finish, beautiful and generous.

5. Good processing performance: stainless steel welded pipe has good processing performance, and can be cut, bending, welding and other processing operations as needed.

Stainless steel welded pipe has the characteristics of simple manufacturing process, obvious advantages and a wide range of application fields. With the continuous progress of science and technology and the development of industry, the application prospect of stainless steel welded pipe will be broader. At the same time, we also need to constantly improve the stainless steel welded pipe manufacturing industry I art, improve the quality and performance of products, to meet the needs of different industries for pipe materials.

Spiral welded pipe: it is to roll low carbon carbon structural steel or low alloy structural steel strip according to a certain spiral Angle (called forming Angle) into the pipe blank, and then weld the pipe seam to make, it can use narrow strip steel to produce large diameter steel pipe. The al welded pipe is mainly used for oil and natural gas transmission pipeline, and its specifications are indicated by outer diameter * wall thickness. The single-sided and double-sided welded pipe shall ensure that the hydraulic test, tensile strength and cold bending performance of the weld shall comply with the provisions.

Product Detail

|

Steel Grade: |

A214 A178 A423 A513 A53/A53M A672 API 5L APE 3PE Q235 Q345 St37 St52 |

|

Standard: |

ASME/ASTM SA/A214 A178 A423 A513 A672 A53 A500,A213,A312,A269,A778,A789, GB/T3091 GB/T3094;DIN EN10025; DIN EN10217-2005; BS EN10217; BS EN10219; BS EN10025; |

|

Specification: |

OD(1/2″-60″) or Customized |

|

Wt: |

1.0-30mm,or according to customer’s special request |

|

Length: |

1-20meters,or according to customer’s special request |

|

Package: |

Export Standard Package |

|

Pipe ends: |

(1)Plain (2)Beveled (3)Threaded with coupling and plastic cap |

|

End protector: |

(1) Plastic cap (2) Iron protector (3) as request |

|

Surface Treatment: |

(1) Bared (2) Black Painted (3) Oiled |

|

Application: |

Construction,machine structure pipe, Agriculture equipment pipe,Water and gas pipe, Greenhouse pipe, Scaffolding pipe, Building material tube, Furniture tube, Low pressure fluid tube, Oil pipe, etc. |

|

Mill MTC: |

Supplied before shipment |

|

Inspection: |

The Third Party inspection can be accepted,SGS,BV,TUV |

|

Mount port: |

Any port in China |

|

Trade Term: |

FOB,CIF,CFR,EXW,etc. |

|

Price Term: |

TT or LC at sight |

|

Our services: |

We can customized according to customer’s requriement or drawing ,packaging according to customers’ request |

Factory Show