Alloy Stainless Copper Steel Fin Tube

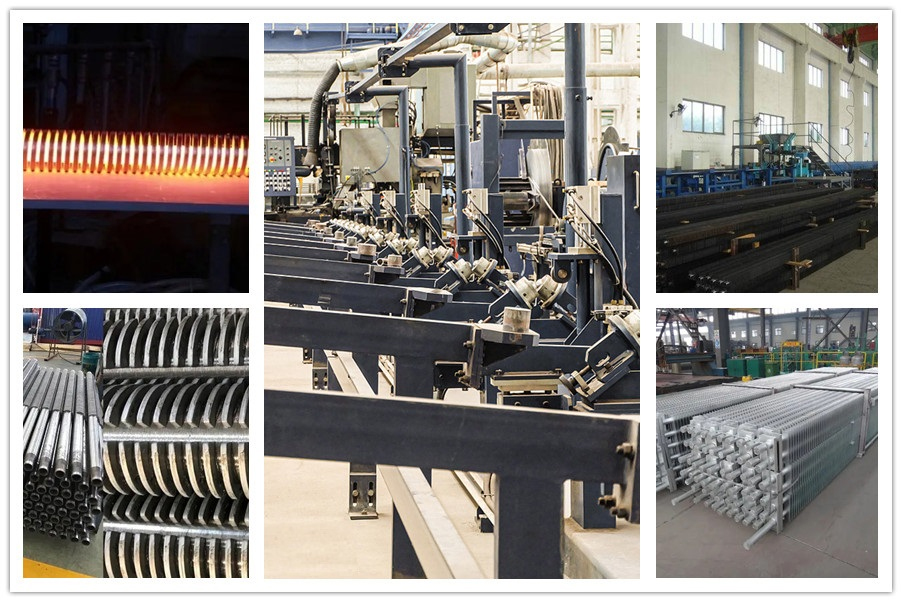

Product presentation

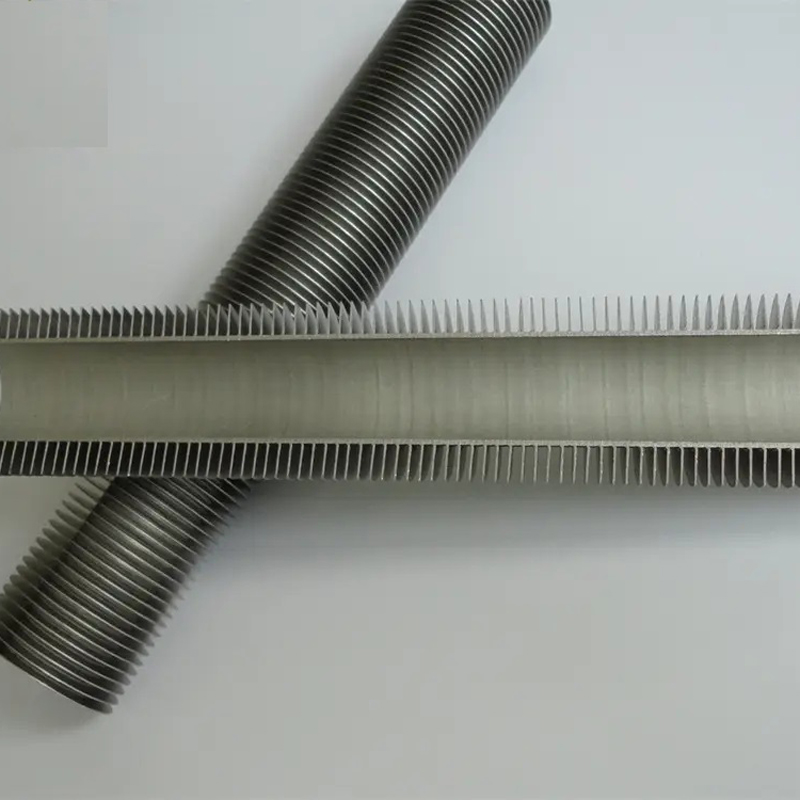

High-frequency welded spiral fin tube is a tubular efficient heat transfer element with spiral fin. The extended surface (fins) can be solid or serrated, dozens of times more than the heat transfer area of a bare tube.

The processing process of steel and aluminum cold rolled wing pipe is made from aluminum pipe and steel pipe, and then formed into fin after mechanical cold rolling.

Using the physical characteristics of the aluminum tube, the steel tube as the core and the cold rolled aluminum fin are closely combined.

The composite fin tube has the following characteristics:

1. High heat transfer performance and low contact thermal resistance;

2. The contact area of the fin and the tube is large, closely fit and firm;

3. Good corrosion resistance and stable long-term use performance;

4. The wing steel performance is good, not easy to deform.

Widely used in steel, petroleum, chemicals, machinery, shipbuilding, power stations and hospitals and food industries.

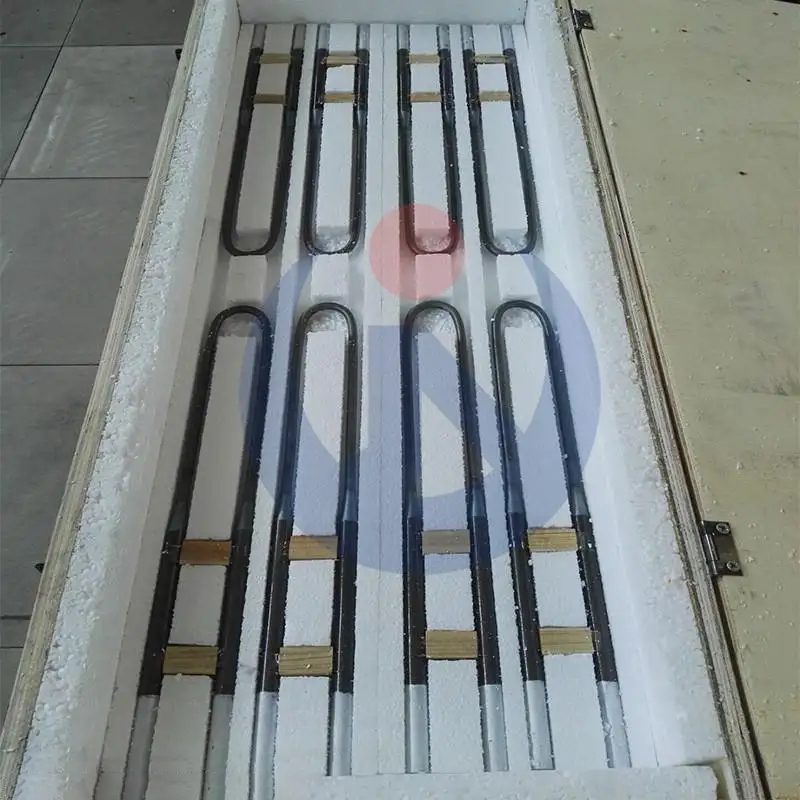

Insaic G fin tube processing technology: the fin is tightly embedded in the outer surface of the mechanically slotted base tube. Base pipe material: carbon steel, alloy steel, stainless steel, double-phase steel, copper pipe. Fings: aluminum 1060, aluminum 1100, T2 copper usage: air cooler, heat exchanger, heater, economizer applications: ● oil, chemical and petrochemical industry ● gas processing ● steel industry: blast furnace and converter system ● power generation: steam turbine exhaust condensation, condensate contact cycle cooling condensation, fossil and nuclear power plant ● air conditioning (freon, ammonia, propane) ● waste incineration equipment ● compressor cooler, etc

Product Detail

Heat Exchanger Finned Tube

1. Extruded Fin Tube

| TUBE MATERIAL: | All Kind of Material can be applied |

| FIN MATERIAL: | Aluminum A1100 |

| TUBE SIZE: | 15.88~50.8 |

| FIN SIZE: | 7~11.5FPI(Fin Height Max 16mmH) |

2. L-Foot Fin Tube

| TUBE MATERIAL: | All Kind of Material can be applied |

| FIN MATERIAL: | Copper C1100, C1220 |

| TUBE SIZE: | 12.70~50.8 |

| FIN SIZE: | 7~11.5FPI(Fin Height Max 16mmH) |

3. G-Fin Tube

| TUBE MATERIAL: | All Kind of Material can be applied |

| FIN MATERIAL: | Aluminum A1100, A1050, A1060 |

| TUBE SIZE: | 12.70~50.8 |

| FIN SIZE: | 7~11.5FPI(Fin Height Max 16mmH) |

4. High Frequency Welded Finned Tube

| TUBE MATERIAL: | ASME SA179 Carbon Steel Tube /Stainless Steel Tube /Alloy Steel Material |

| FIN MATERIAL: | Carbon Steel Tube /Stainless Steel Tube /Alloy Steel Material |

| TUBE SIZE: | 12.70~160 |

| FIN SIZE: | 1.5~7FPI |

5. Copper Alloy High Finned Tube

| TUBE MATERIAL: | C12200, C11000, C70600 |

| FIN MATERIAL: | C12200, C11000, C70600 |

| TUBE SIZE: | 15.88~22.23 |

| FIN SIZE: | 5~9FPI(Max 12mm. H) |

6. Oval Finned Tube

| TUBE MATERIAL: | Carbon Steel Tube /Stainless Steel Tube / Alloy Steel Material /Copper Alloy Tube |

| FIN MATERIAL: | Carbon Steel Tube /Stainless Steel Tube / Alloy Steel Material /Copper Alloy Tube |

| TUBE SIZE: | All Size Available |

| FIN SIZE: | 5~15FPI |

Our Services: We can customized according to customer’s requriement or drawing ,packaging according to customers’ request

Mount port: Any port in China

Trade Term: FOB,CIF,CFR,EXW,etc.

Price Term: TT or LC at sight