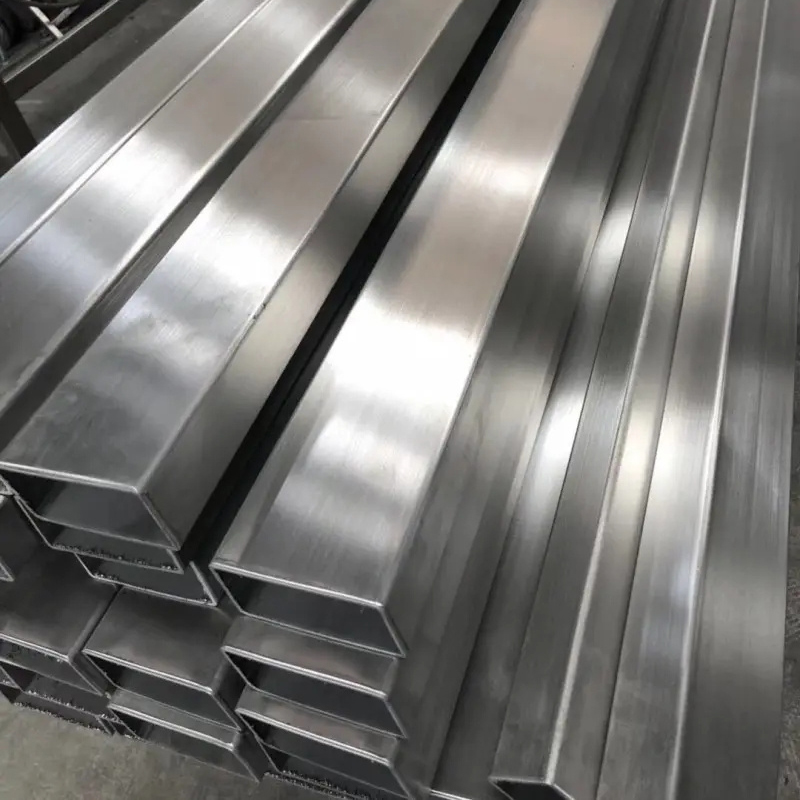

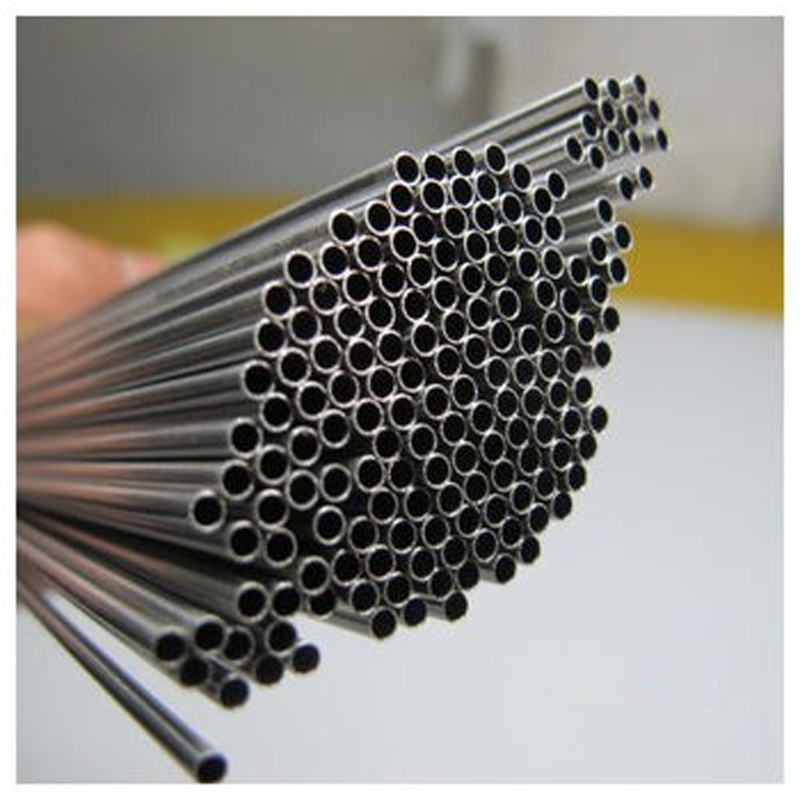

API 5L 3PE Q345 St37 St52 Welded Pipe, ERW, Spiral Welded Pipe

Welding pipe process

Raw material open-roll-leveling-end shear and welding-live sleeve-forming-welding-internal and external welding bead removal-pre-correction-induction heat treatment-setting and calibration-eddy current detection-cut-hydraulic inspection-pickling-final inspection (strict check) -packaging-shipment.

3pe anticorrosion steel pipe base material includes seamless steel pipe, spiral steel pipe and straight seam steel pipe. The polyethylene (3PE) anticorrosive coating has been widely used in the petroleum pipeline industry for its good corrosion resistance, water and gas permeability and mechanical properties.

3PE anticorrosion generally consists of three layers of structure:

First layer of epoxy powder (FBE & gt; 100um)

The second layer of adhesive (AD) is 170~250um

Third layer of polyethylene (PE)1.8~3.7mm

Spiral welded pipe: it is to roll low carbon carbon structural steel or low alloy structural steel strip according to a certain spiral Angle (called forming Angle) into the pipe blank, and then weld the pipe seam to make, it can use narrow strip steel to produce large diameter steel pipe. The al welded pipe is mainly used for oil and natural gas transmission pipeline, and its specifications are indicated by outer diameter * wall thickness. The single-sided and double-sided welded pipe shall ensure that the hydraulic test, tensile strength and cold bending performance of the weld shall comply with the provisions.

The inspection of the internal defects of the welded pipes is generally conducted by nondestructive testing. The current nondestructive testing includes magnetic, ultrasonic, radiation, penetration and so on.

Product Detail

|

Steel Grade: |

A214 A178 A423 A513 A53/A53M A672 API 5L APE 3PE Q235 Q345 St37 St52 |

|

Standard: |

ASME/ASTM SA/A214 A178 A423 A513 A672 A53 A500,A213,A312,A269,A778,A789, GB/T3091 GB/T3094;DIN EN10025; DIN EN10217-2005; BS EN10217; BS EN10219; BS EN10025; |

|

Specification: |

OD(1/2″-60″) or Customized |

|

Wt: |

1.0-30mm,or according to customer’s special request |

|

Length: |

1-20meters,or according to customer’s special request |

|

Package: |

Export Standard Package |

|

Pipe ends: |

(1)Plain (2)Beveled (3)Threaded with coupling and plastic cap |

|

End protector: |

(1) Plastic cap (2) Iron protector (3) as request |

|

Application: |

Construction,machine structure pipe, Agriculture equipment pipe,Water and gas pipe, Greenhouse pipe, Scaffolding pipe, Building material tube, Furniture tube, Low pressure fluid tube, Oil pipe, etc. |

|

Mill MTC: |

Supplied before shipment |

|

Inspection: |

The Third Party inspection can be accepted,SGS,BV,TUV |

|

Mount port: |

Any port in China |

|

Trade Term: |

FOB,CIF,CFR,EXW,etc. |

|

Price Term: |

TT or LC at sight |

|

Our services: |

We can customized according to customer’s requriement or drawing ,packaging according to customers’ request |

Factory Show