-

Check Valve, Pressure Reducing Valve, Drain Valve, Instrument Valve

The valve is the control component in the fluid conveying system, with the functions of cut-off, regulation, diversion, preventing countercurrent, pressure stabilization, diversion or overflow pressure relief.

Valvalve used in fluid control system, from the most simple stop valve to the extremely complex automatic control system, its varieties and specifications are quite various. Valves can be used to control the flow of various types of fluids such as air, water, steam, various corrosive media, mud, oil, liquid metal and radioactive media. According to the material, the valve is also divided into cast iron valves, cast steel valves, stainless steel valves (201,304,316, etc.), chromium molybdenum steel valves, chromium molybdenum vanadium steel valves, dual-phase steel valves, plastic valves, non-standard customized valves, etc.

-

Flat Welding Flange/ Welding Neck Flange/ Screwed Flange

Product presentation:

Welding flange connection is to put two pipes, pipe fittings or equipment, first each fixed on a welding. Between the two welds, plus flanged pads, were fastened together with bolting to complete the connection. Welding is an important connection mode for high-pressure pipeline construction. The welding flange connection is easy to use and can withstand large pressure.

-

Carbon steel Pipe Fitting A234WPB A420WPL6 ST35.8

Product presentation:

The main products of carbon steel pipe fittings include carbon steel elbow, carbon steel flange, carbon steel tee, carbon steel tee, carbon steel special diameter pipe (large and small head), carbon steel head (pipe cap), etc. The main implementation standards include national standard, American standard, Japanese standard, etc., among which the national standard also includes the Ministry of Chemical Industry standard, Sinopec pipe fittings standard, power pipe fittings standard. Carbon steel pipe fittings are the general term for the connection, control, replacement, shunt, sealing and support components in the pipe system. A pipe fitting is a component that connects a pipe to a pipe. High pressure pipe fittings are suitable for high pressure steam equipment, chemical high temperature and high pressure pipeline, power plant and nuclear power plant pressure vessels, high pressure boiler accessories and other special environments. Pipe fittings are widely used in construction, chemical industry, mining, energy and many other engineering fields. Its important role should not be overlooked.

-

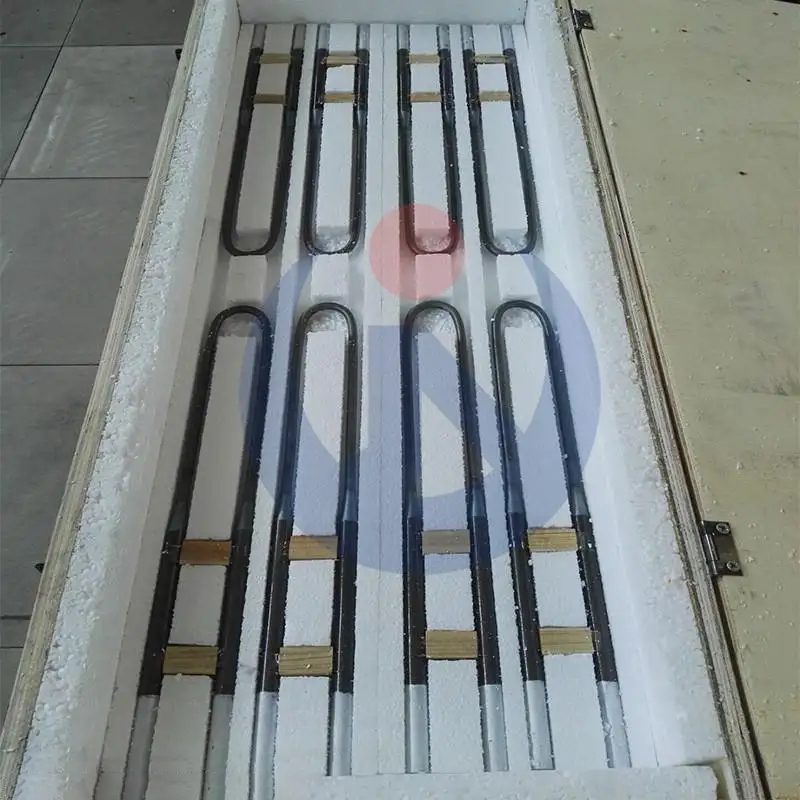

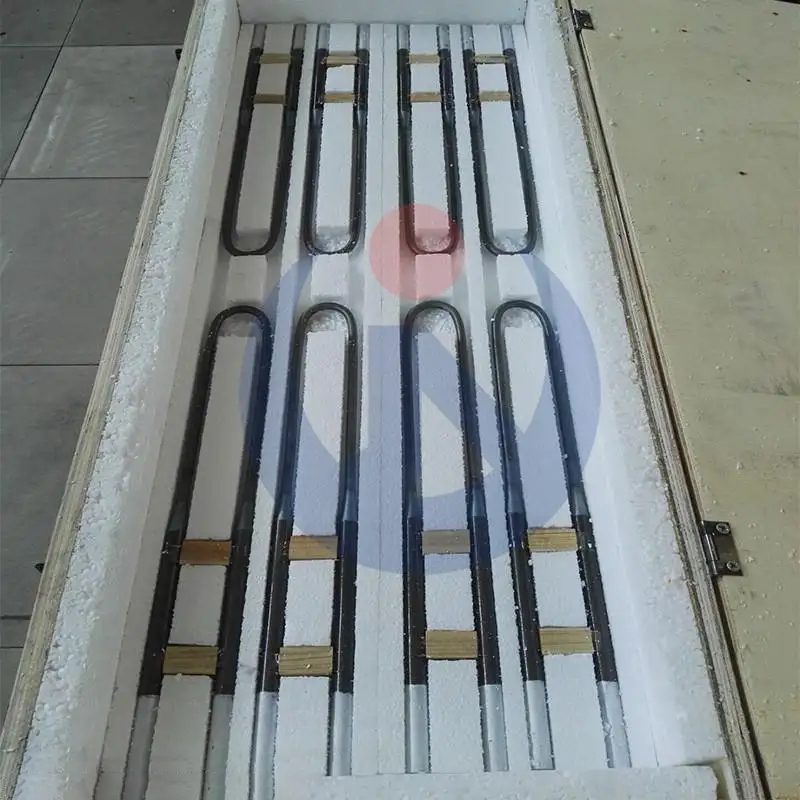

U Tubing Heat Exchanger Tube/ U bend tube/Boiler Tube

Product presentation:

‘U’ bending is done by cold working process.

‘U’ bending is done to the required radius as per customer drawings.

The bend portion and six inch leg is stress relieved by resistance heating.

Inert gas (Argon) is passed through it at the required flow rate to avoid oxidation in ID.

The radius is checked for its OD and wall thinning with the recommended specification.

The physical properties and micro-structure is checked at three different position.

Visual inspection for waviness and cracks is done with Dye Penetrant Test.

Each tube is then hydro tested at the recommended pressure to check for leakage.

Cotton ball test is done to check the ID cleanliness of the tube.

Thereafter pickled, dried, marked and packed.

-

A234 WPB SS400 ST35.8 P235GH Carbon Steel Elbow

Product presentation:

In a piping system, the elbow is a pipe fitting that changes the direction of the piping. According to the Angle, there are three most commonly used 45° and 90°180°, in addition to the engineering needs and other abnormal Angle bends such as 60° according to the project. The materials of the elbow include cast iron, stainless steel, alloy steel, forgable cast iron, carbon steel, non-ferrous metals and plastics.

The ways of connecting with the pipe are: direct welding (the most commonly used way) flange connection, hot melt connection, electric melt connection, thread connection and plug connection, etc. According to the production process, it can be divided into: welding elbow, stamping elbow, push elbow, casting elbow, butt welding elbow, etc. Other names: 90-degree bend, right-angle bend, etc.

-

Alloy Steel Pipe Fitting A234WP12 P1 PA22 P5

Product presentation:

Alloy Steel Pipe fittings are a general term of the parts connecting, controlling, changing, diverting, sealing and supporting in the pipe system. A pipe fitting is a part that connects the pipe into a pipe. High pressure pipe fittings are suitable for high pressure steam equipment, chemical high temperature and high pressure pipeline, power plant and nuclear power plant pressure vessels, high pressure boiler accessories and other special environment. Pipe fittings are widely used in many engineering fields such as construction, chemical industry, mining and energy. Its important role should not be ignored.

-

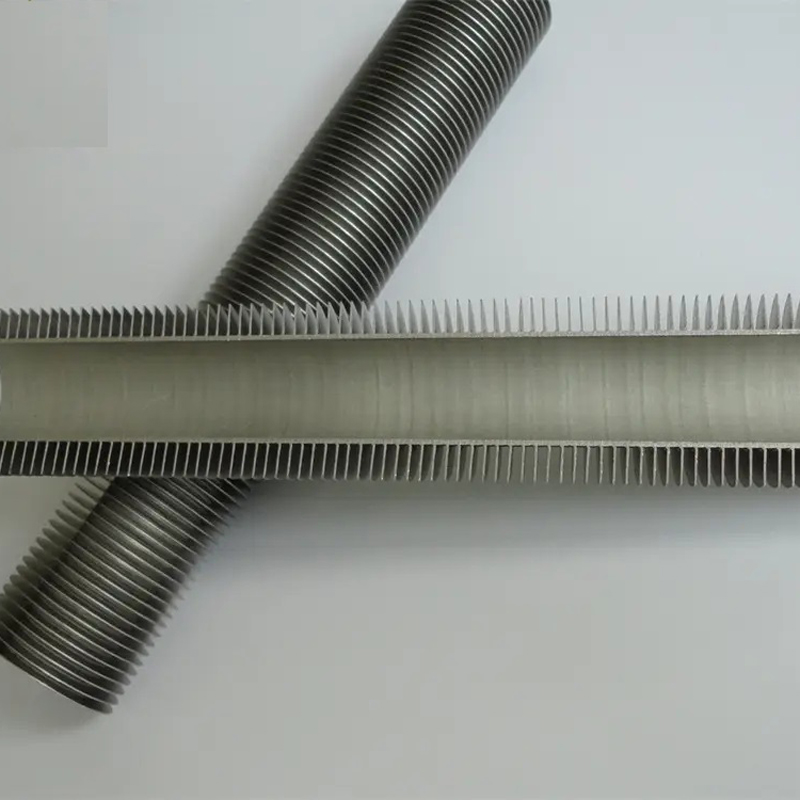

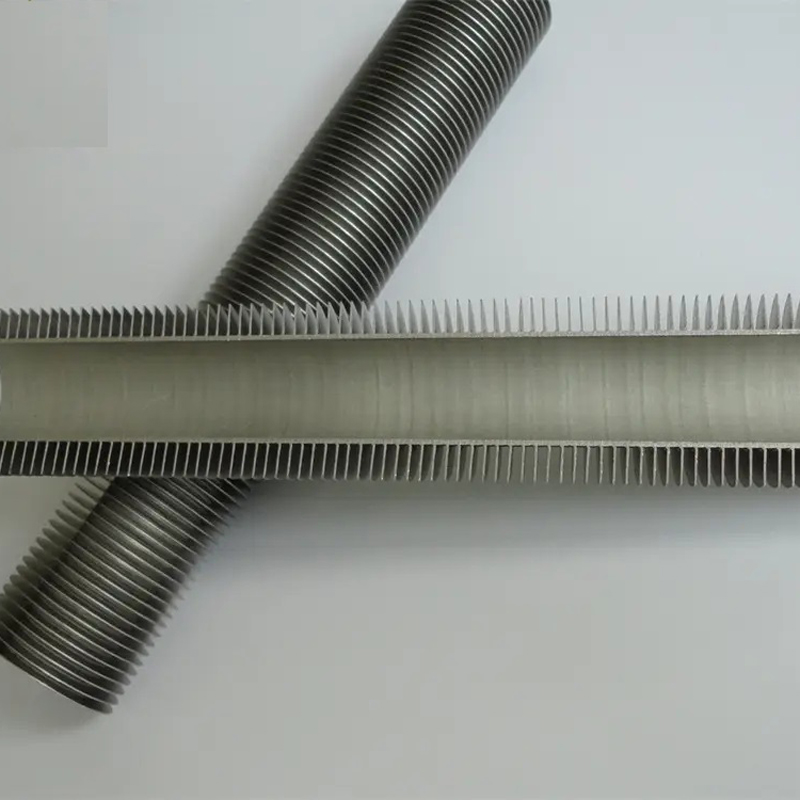

Heat Exchanger Finned Tube

Product presentation:

Wing tube heat exchanger is a tubular heat exchanger with wings, which can be composed of one or several fin tubes and can have a shell or shell. It is a new heat exchanger suitable for gas-liquid and steam-liquid that can be customized according to the parameter conditions; fin tube is the basic component of the fin heat exchanger. In order to improve the heat exchange efficiency, fins are usually added on the surface of the heat exchanger tube, so as to increase the outer area of the heat transfer tube, so as to achieve the purpose of improving the heat transfer efficiency.

-

304, 310S, 316, 347, 2205 Stainless Pipe Fitting

Product presentation:

Stainless Pipe fittings are a general term of the parts connecting, controlling, changing, diverting, sealing and supporting in the pipe system. A pipe fitting is a part that connects the pipe into a pipe. High pressure pipe fittings are suitable for high pressure steam equipment, chemical high temperature and high pressure pipeline, power plant and nuclear power plant pressure vessels, high pressure boiler accessories and other special environment. Pipe fittings are widely used in many engineering fields such as construction, chemical industry, mining and energy. Its important role should not be ignored.

-

Alloy Stainless Copper Steel Fin Tube

Product presentation:

The trapezoidal section formed by the calendering of the L-shaped fin tube is compatible with the size of the density distribution of heat flow, and the segment is closely combined and the thermal efficiency is high, which eliminates the contact thermal resistance caused by the segment gap.

Operating temperature: 230℃

Characteristics: the use of winding process, high production efficiency, uniform distance, good heat transfer, high wing ratio ratio, the base tube can be protected from air erosion.

Application: mainly used in petrochemical, electric power, paper, tobacco, building heating and other industries of air cooler, air heater and food industry plant protein powder, starch and other spray drying system of air heater. -

Stainless Steel/ Nickle Alloy U Bend Tubes

Product presentation:

The U tube is usually used to exchange heat in process fluids with large radiators. The fluid is pumped out along a pipe, then through a U-junction, and back along a pipe parallel to the inflow line. Heat is transferred through the wall of the tube to the wrapping material. This design is used for industrial applications, where many U tubes can be poured into oil containers containing high heat capacity.

-

304, 310S, 316, 347, 2205 Stainless Flange

Product presentation:

Flange, also known as flange flange disc or rim. Usually refers to opening at the periphery of a disk-like metal body. Several fixed holes are used to connect other parts and are widely used in various mechanical equipment and pipe connections. Flange is parts connected between shaft and shaft for connection between pipe ends and also used at the inlet and outlet of equipment for connection between two devices such as reducer flange.

Flange is an important element connecting pipes and is widely used in various industrial fields. Its main function is to connect the pipe, so that the pipe system has good sealing and stability. Flanges are applicable to a variety of piping systems. Flanges can be connected to various pipes, including water pipes, windpipes, pipe pipes, chemical pipes and so on. Whether in petrochemical, power shipbuilding, food processing, medicine and other industries, can see flange. Flanges cover a wide range of piping systems, media, pressure levels and temperature ranges. In the industrial production, the correct selection and use of flange is an important guarantee to ensure the safe operation of the pipeline system.

-

304, 310S, 316, 347, 2205 Stainless Cut – Off Valve, Ball Valve, Butterfly Valve

Product presentation:

A valve is a device used to control the direction, pressure and flow of a fluid system. It is a device to flow or stop the medium (liquid, gas, powder) in the pipe and the equipment and control its flow rate.

The valve is the control component in the pipeline fluid delivery system, used to change the access section and medium flow direction, with the functions of diversion, cut-off, throttle, check, diversion or overflow pressure discharge. Valves used for fluid control, from the most simple stop valve to the extremely complex automatic control system used in a variety of valves, its various varieties and specifications, the nominal diameter of the valve from a very small instrument valve to the diameter of 10m industrial pipeline valve. It can be used to control the flow of various types such as water, steam, oil, gas, mud, various corrosive media, liquid metal and radioactive fluid. The working pressure of the valve can range from 0.0013MPa to 1000MPa, and the working temperature can be c-270℃ to high temperature of 1430℃.