Check Valve, Pressure Reducing Valve, Drain Valve, Instrument Valve

Classification by function and use

(1) Cut: such as gate valve, stop valve, cock valve, ball valve, butterfly valve, needle type valve, diaphragm valve, etc. Cut-off valve is also known as closed valve, stop valve, its function is to connect or cut off the medium in the pipeline.

(2) Check class: such as check valve, check valve is also known as one-way valve or check valve, check valve belongs to an automatic valve, its function is to prevent the medium in the pipeline backflow, prevent the pump and drive motor reversal, as well as the leakage of the container medium. The bottom valve of the pump pump also belongs to the check valve class.

(3) Safety category: such as safety valve, explosion-proof valve, accident valve, etc. The function of the safety valve is to prevent the medium pressure in the pipeline or device from exceeding the specified value, so as to achieve the purpose of safety protection.

(4) regulating class: such as regulating valve, throttle valve and pressure reducing valve, its role is to adjust the medium pressure, flow and other parameters.

(5) shunt category: such as distribution valve, three-way valve, drain valve. Its function is to distribute, separate, or mix the medium in the line.

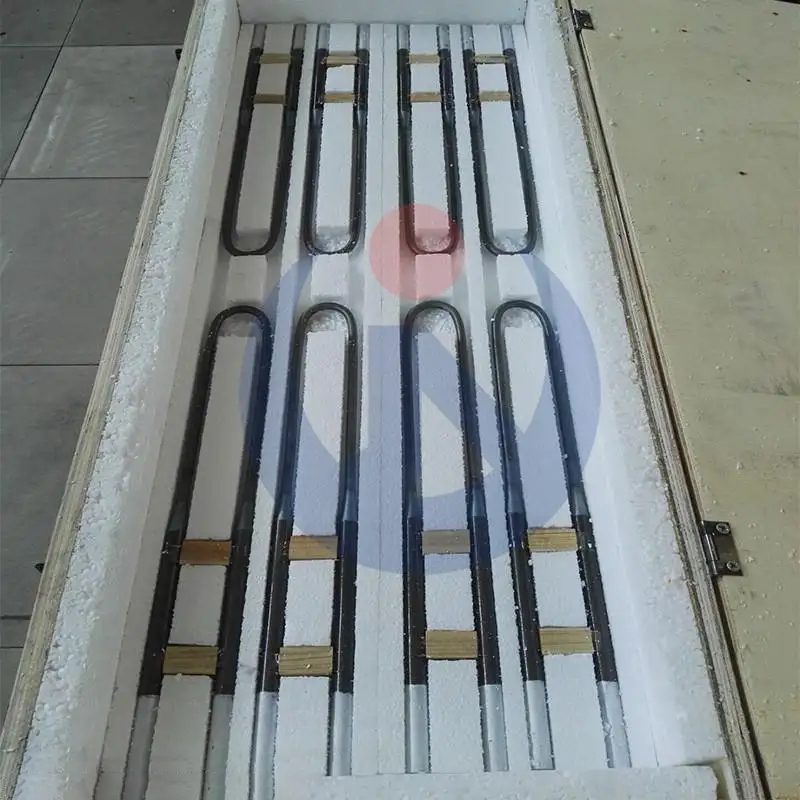

(6) Special purposes: such as pigging valve, vent valve, sewage discharge valve, exhaust valve, filter, etc. The exhaust valve is an essential auxiliary component in the pipe system, which is widely used in boiler, air conditioning, oil and gas, water supply and drainage pipe. Often installed in the commanding point or elbow, etc., to eliminate excess gas in the pipeline, improve the efficiency of pipe road and reduce energy consumption.

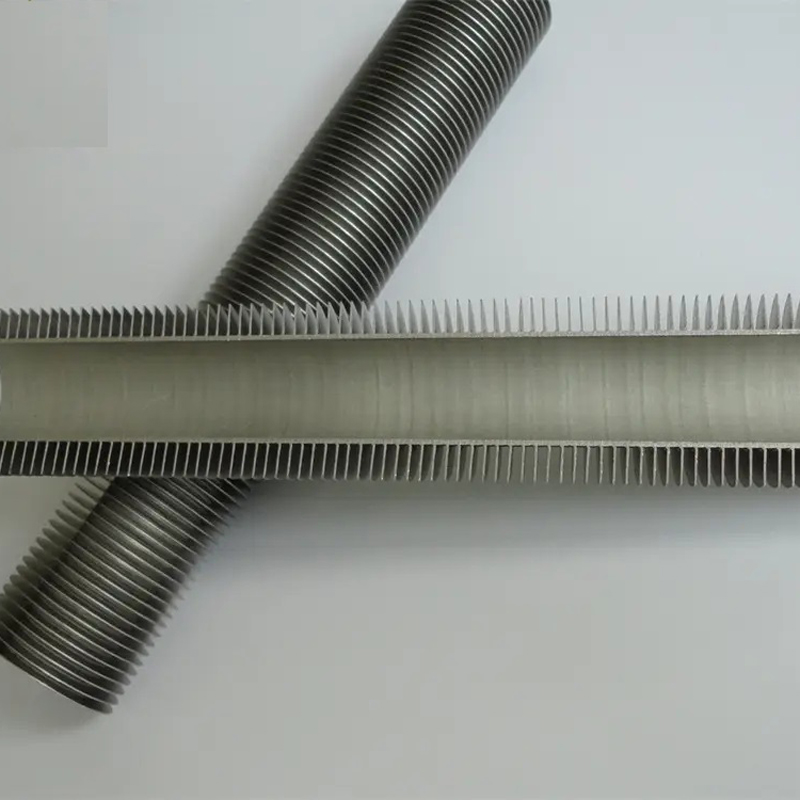

Folold are classified by the ligation method

(1) Threaded connection valve: the valve body has internal thread or external thread, and is connected with the pipe thread.

(2) Flange connection valve: the valve body with a flange, connected with the pipe flange.

(3) Welding connection valve: the valve body has a welding groove, and it is connected with the pipe welding.

(4) clamp connection valve: the valve body has a clamp, connected with the pipe clamp.

(5) The sleeve connection valve: connect the pipe with the sleeve.

(6) pair the joint valve: use bolts to directly clamp the valve and the two pipe together.

Product Detail

|

Name: |

Cut – Off Valve, Ball Valve ,Butterfly Valve, Check Valve, Pressure Reducing Valve, Drain Valve, Regulating Valve, And Water Discharge Valve, Throttle Valve, Instrument Valve, Filter |

|

Standard |

DIN, GB, BSW, JIS |

|

Main Material |

BS5163 DIN3202 API609 En593 BS5155 En1092 ISO5211 |

|

Specification |

Order according to customer requirements |

|

Application |

Food and Medical Industry |

|

Surface Treatment |

Polishing |

|

Machining Tolerance |

up to +/- 0.1mm, According to Customer Drawing |

|

Applications : |

Petroleum, chemical, machinery, boiler,electric power, shipbuilding, construction, etc |

|

Delivery time |

after receipt of advanced payment ,Common size large quantity in stock |

|

Payment term: |

T/T, L/C, D/P |