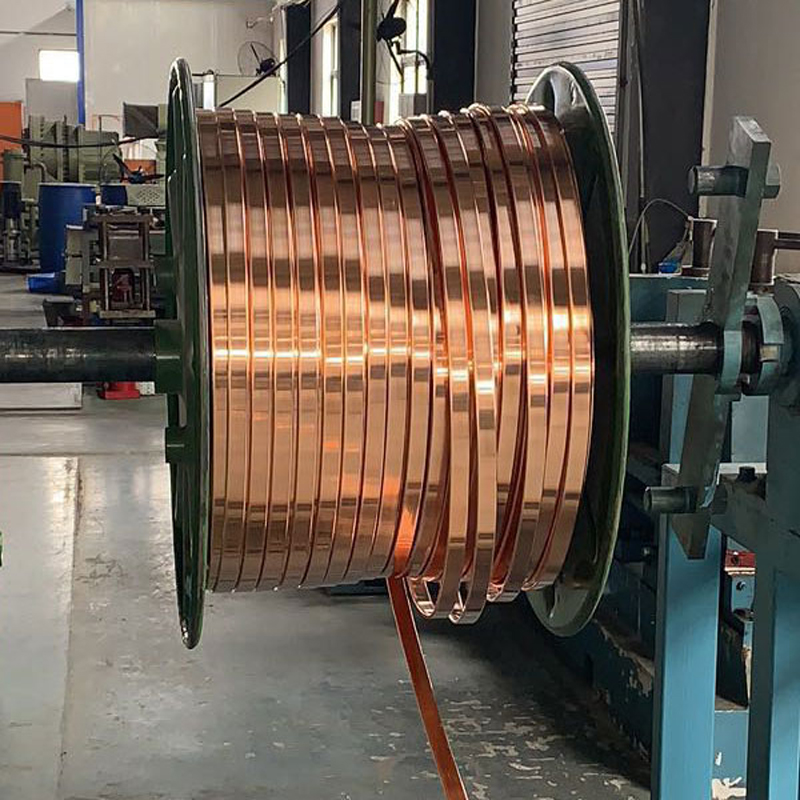

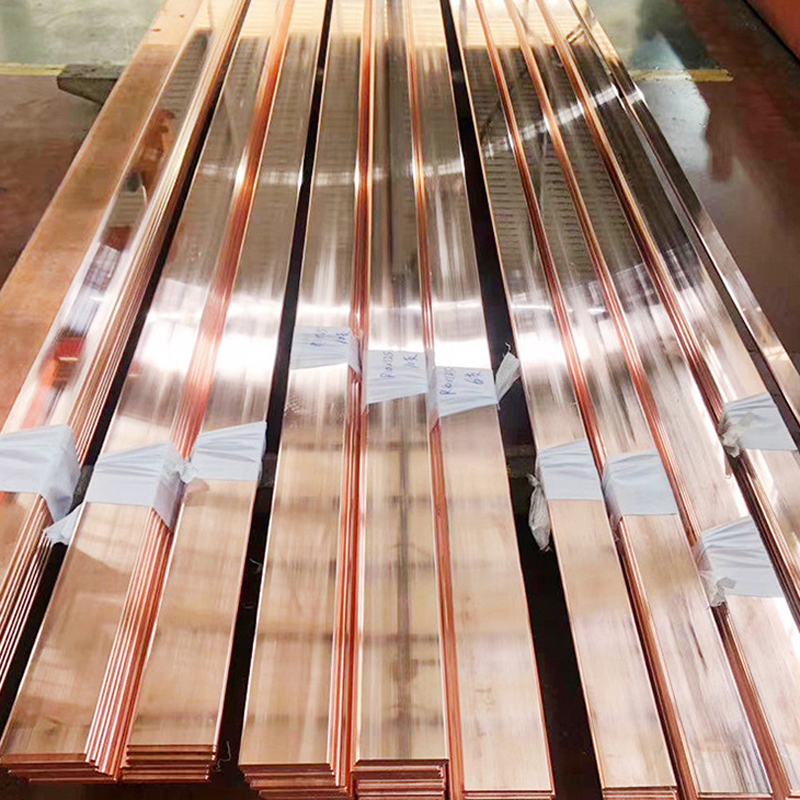

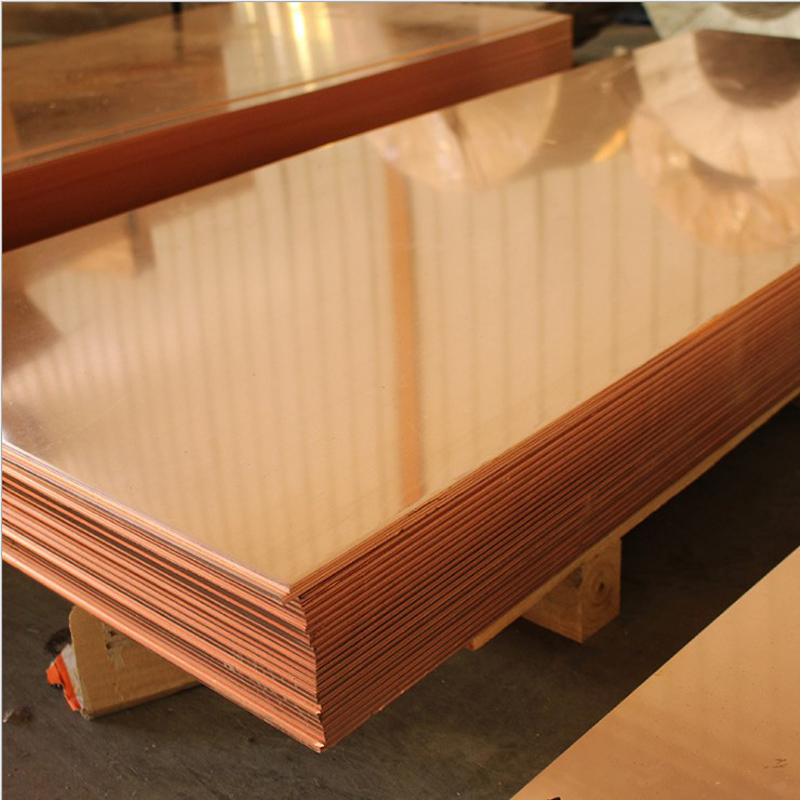

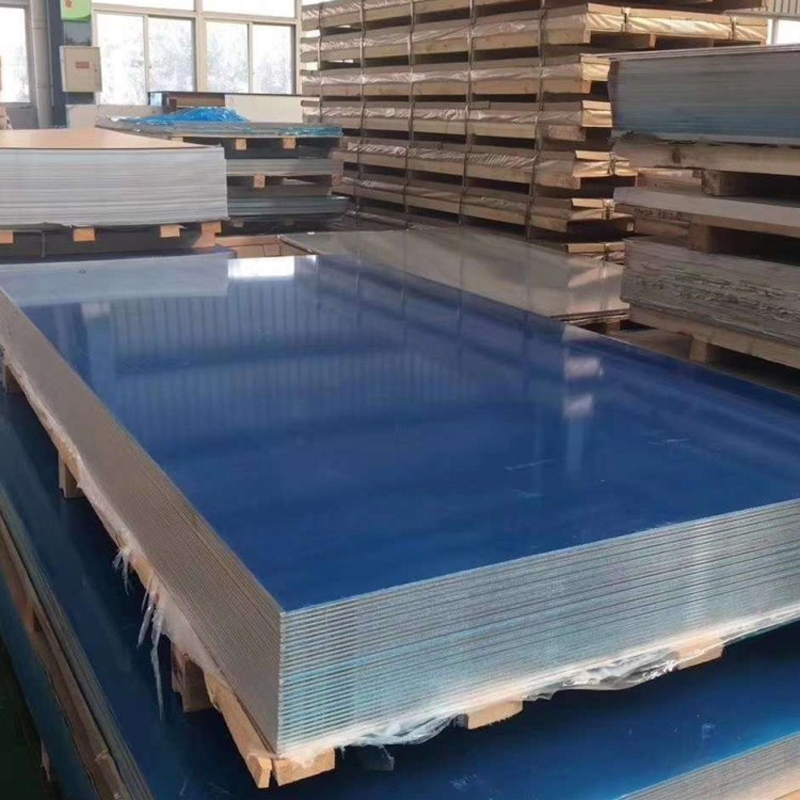

Copper Strips, Copper Sheet, Copper Sheet Coil, Copper Plate

Product presentation

Pure copper plus nickel can significantly improve the strength, corrosion resistance, hardness, resistance and thermoelectric properties, and reduce the coefficient of resistivity temperature. So white copper than other copper alloy mechanical properties, physical properties are very good, good ductility, high hardness and beautiful color, corrosion resistance, rich deep impact properties, is widely used in shipbuilding, petrochemical, electrical appliances, instruments, medical instruments, equipment, daily necessities, handicrafts and other fields, and is important resistance and thermocouple alloy. The disadvantage of white copper is that the main addition element —— nickel is a scarce strategic material, and the price is relatively expensive.

Brass is an alloy composed of copper and zinc. Brass composed of copper and zinc is called ordinary brass. If it is composed of more than two elements, it is called special brass. Brass has strong wear resistance, brass is often used in the manufacture of valves, water pipes, air conditioning inside and outside the machine connection pipe and radiator.

Purple copper, also known as red copper, has very good electrical conductivity and thermal conductivity, excellent plasticity, easy to thermal pressure and cold pressure processing, a large number of wire, cable, brush, spark special electrocorrosion copper and other requirements of good conductivity products.

The electrical conductivity and thermal conductivity of purple copper is second only to silver, which is widely used in the production of conductive and thermal conductivity equipment. Copper has good corrosion resistance in the atmosphere, seawater and some non-oxidized acid (hydrochloric acid, dilute sulfuric acid), alkali, salt solution and a variety of organic acids (acetic acid, citric acid), and is used in the chemical industry. In addition, copper has good weldability, can be cold, thermoplastic processing into a variety of semi-finished products and finished products. In the 1970s, purple copper production exceeded the total output of all other types of copper alloys.

Product Detail

| Product Name | Copper Strips |

| Shape | Coil/Strip/Plate/Sheet/Bar/Rod/Pipe/Tube/Wire |

| Size | Regular size 600x1500mm or Customized |

| Grade | Pure Copper:C10100/C10200/C11000/C12000/C12200 Copper Alloy:C14500/C17200/C17300/C17510/C18150/C19200/C19210/C19400 Brass:C22000/C23000/C24000/26000/26800/27000 Lead Brass:C33000/CuZn36Pb3/C35000/C35300/C36010/C37000/37700/C38000/C38500/CuZn39Pb3/CuZn40Pb2 Tin Brass:C44300/C44500/C46400/HSn90-1 Aluminum Brass:C68700/HAl77-2/HAl66-6-3-2/HAl64-3-1 Tin Bronze:C51000/C51100/C51900/C52100/C54400/CuSn4/CuSn5/CuSn5Pb1/CuSn6/CuSn8 Aluminum Bronze:C60800/C61300/C61900/C62300/C63000 Copper Nickel Alloy:C70400/C71500/C70600/C70620/C73500/75200/76200/C77000H59、H62、H63、H70、H80、H90、H96、TU0-TU2;QSn8-0.3、QSn4-0.3、BZn18-18、BZn15-20、CuBe2 |

| Standard | ASTM B280/B111/B152/B88/B49/B359/B505 |

| Temper | H,1/2H,3/4H,1/4H,EH,SH,O60 and etc. |

| Surface | Mill,Polished,bright or customized. |

| MOQ | 100kg |

| Delivery Time | 5-10 days after the payment received |

| Payment Item | 30% TT deposit+70% TT balance before delivery |