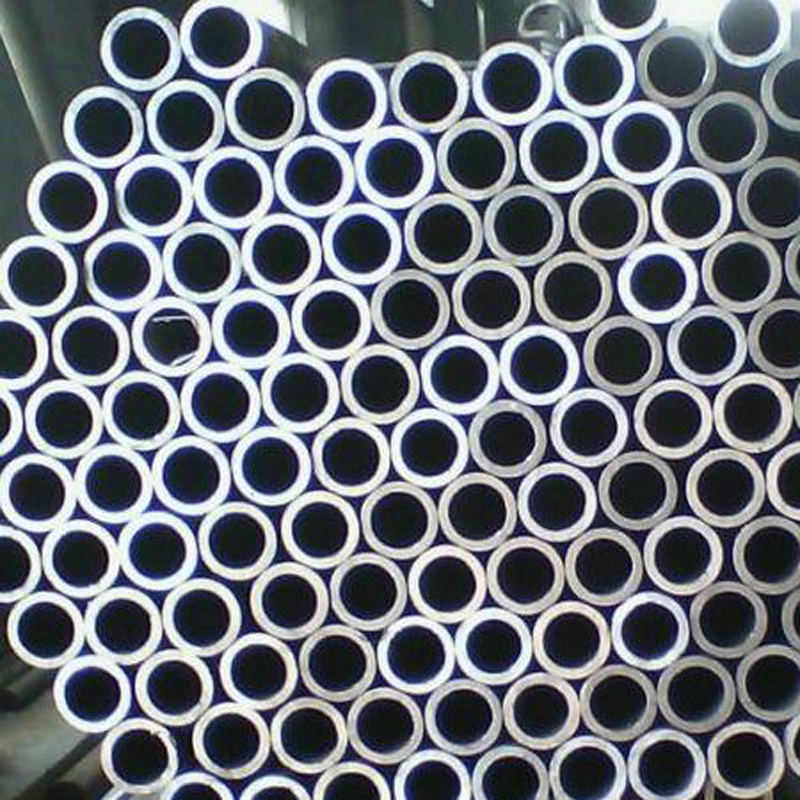

P235GH ST35.8 SA192 Carbon Steel Seamless Pipe / Boiler Tube

Product presentation

The mechanical properties of boiler pipe is an important index to ensure the final service performance (mechanical properties) of steel, which depends on the chemical composition and heat treatment system of steel. In the steel pipe standard, according to different use requirements, stipulate the tensile performance (tensile strength, yield strength or yield point, elongation), as well as the hardness and toughness indicators, as well as the high and low temperature performance required by users.

① The use temperature of the general boiler pipe is below 350℃, and the domestic pipe is mainly made of 10 and 20 carbon junction steel hot rolled pipe or cold pull pipe. Foreign countries mainly used P235GH, SA192, ST35.8,106B, 210A1,210C

② High pressure boiler pipe is often used in high temperature and high pressure conditions, pipe under the action of high temperature flue gas and water vapor, oxidation and corrosion will occur. The required steel pipe has high durable strength, high oxidation and corrosion resistance, and good tissue stability.

Boiler pipe is mainly used to manufacture water wall pipe, boiling water pipe, superheated steam pipe, superheated steam pipe for locomotive boiler, large and small smoke pipe and arch brick pipe, etc

Quality inspection method of seamless steel pipe

1. Chemical composition analysis: chemical analysis method, instrument analysis (infrared C-S instrument, direct reading spectrometer, zcP, etc.).

2. Surface quality inspection of steel pipe: 100%

A. Ultrasonic detection UT:

B. ET: (electromagnetic induction)

C. MT and leakage detection:

Magnetic flaw detection, suitable for the detection of surface and near-surface defects of ferromagnetic materials.

D. Electromagnetic ultrasonic flaw detection:

No coupling medium is needed, which can be applied to high temperature and high speed, rough and dry steel pipe surface flaw detection.

E. liquid penetrating test:

Fluorescence, coloring, and detecting of steel pipe surface defects.

3. Physical and chemical performance inspection of steel pipe;

4. Process performance inspection of steel pipe:

① Flat test: round sample C-shaped sample (S / D & gt; 0.15) H= (1 + 2) S / (+ S / D)

L=40~100mm per unit length deformation coefficient =0.07~0.08

② Pull test: L=15mm without crack is qualified

③ Expansion and curling test: the top taper is 30°, 40° and 60°

④ Bending test: can replace the flattening test (for large diameter pipe).

Product Detail

|

Steel Grade: |

106B,210A1,210C,P9,P11,T1,T11,T2,T5,T12,T22,T23,T91,T92,P235GH,13CrMo4-5,15Mo3,10CrMo9-10,SA192, ST35.8,ST45.8,STB340,STBA 12-2,API5L,5CT |

|

Standard: |

ASME/ASTM SA/A53/513/106/209/210/213/335/178/179/519 ASME/ASTM SA/A213,A312,A269,A778,A789, DIN 17456, DIN17457,DIN 17459,DIN17175,EN10216,BS3605,BS3059, GB/T3087,GB/T5310 |

|

Specification: |

Outdiameter 10~508mm |

|

Wt: |

1.0-30mm,or according to customer’s special request |

|

Length: |

2-20meters,or according to customer’s special request |

|

Package: |

Export Standard Package |

|

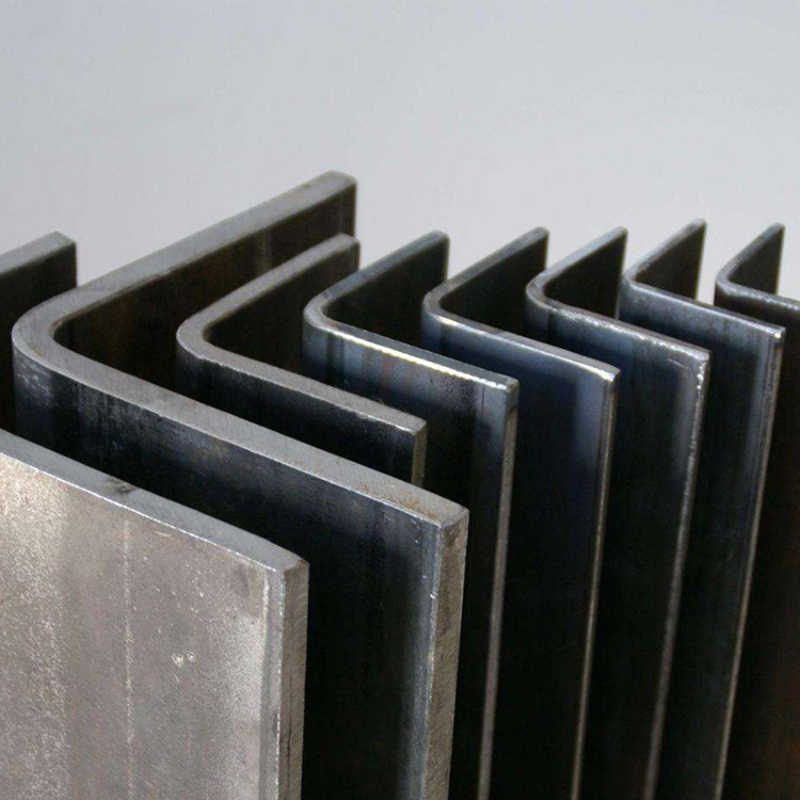

Typies of tube: |

Boiler tube,precision tube,mechanical tubing,cylinder tube,line pipes,etc |

|

Mill MTC: |

Supplied before shipment |

|

Inspection: |

The Third Party inspection can be accepted,SGS,BV,TUV |

|

Mount port: |

Any port in China |

|

Trade Term: |

FOB,CIF,CFR,EXW,etc. |

|

Price Term: |

TT or LC at sight |

|

Our services: |

We can customized according to customer’s requriement or drawing ,packaging according to customers’ request |

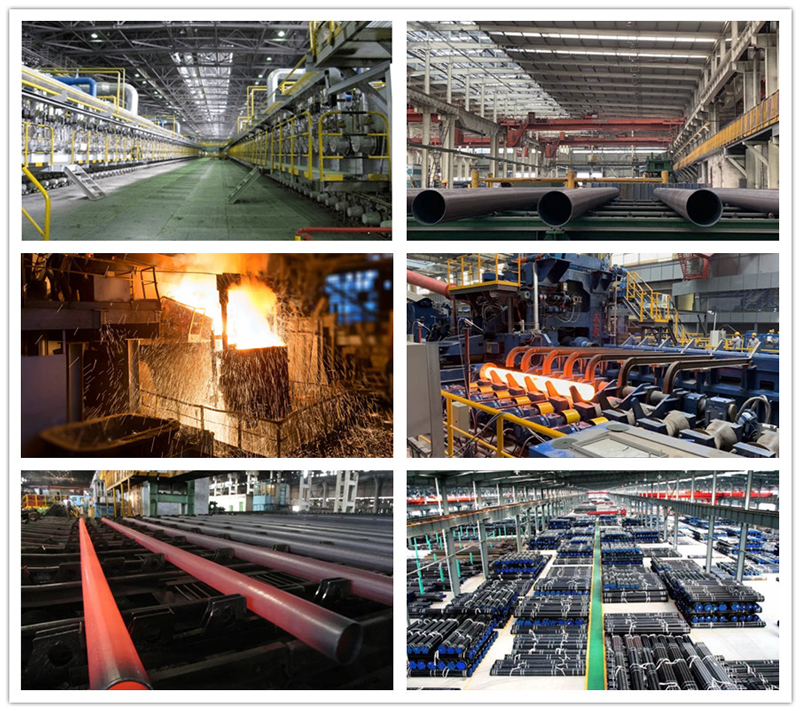

Factory Show