-

13CrMo4-5 ND Alloy Steel Seamless Pipe

09CrCuSb(ND) seamless steel tube for sulfuric acid resistance,low temperature dew point and corrosion

ND steel is a new type of low alloy structural steel, compared with other steel, like low-carbon steel, Corten, CRIA, ND steel has the advantage ofexcellent corrosion resistance and mechanical property. The experimental results showed that the corrosion resistance of ND steel in aqueous solutionlike sulfuric acid, hydrochloric acid and sodium chloride is higher than carbon steel. The most prominent feature is the ability of sulfuric acid dew pointcorrosion resistance; the mechanical property is higher and stable than carbon steel from room temperature to 500 C, and the welding performance isnice. ND steel always used for manufacturing economizer, heat exchanger, air pre-heater, since 1990, ND steel has widely been used in the industry ofpetrifaction and electricity.

-

Check Valve, Pressure Reducing Valve, Drain Valve, Instrument Valve

The valve is the control component in the fluid conveying system, with the functions of cut-off, regulation, diversion, preventing countercurrent, pressure stabilization, diversion or overflow pressure relief.

Valvalve used in fluid control system, from the most simple stop valve to the extremely complex automatic control system, its varieties and specifications are quite various. Valves can be used to control the flow of various types of fluids such as air, water, steam, various corrosive media, mud, oil, liquid metal and radioactive media. According to the material, the valve is also divided into cast iron valves, cast steel valves, stainless steel valves (201,304,316, etc.), chromium molybdenum steel valves, chromium molybdenum vanadium steel valves, dual-phase steel valves, plastic valves, non-standard customized valves, etc.

-

A214 A178 A423 A53 Straight Welded Pipe, ERW, Spiral Welded Pipe

Product presentation:

Stainless steel welded pipe is widely used in petroleum, chemical industry, medicine, food, shipbuilding, environmental protection and other fields. It is made of stainless steel tape coil, has high temperature resistance, corrosion resistance, strong pressure resistance and other characteristics.

-

Flat Welding Flange/ Welding Neck Flange/ Screwed Flange

Product presentation:

Welding flange connection is to put two pipes, pipe fittings or equipment, first each fixed on a welding. Between the two welds, plus flanged pads, were fastened together with bolting to complete the connection. Welding is an important connection mode for high-pressure pipeline construction. The welding flange connection is easy to use and can withstand large pressure.

-

304, 310S, 316, 347, 2205 Stainless Angle Steel

Product presentation:

Stainless steel angle steel, which is a right Angle steel perpendicular to each other. It is steel shaped at right angles on three sides with side and bottom sides. Stainless steel Angle steel is usually made from hot rolled or cold bending, the length and size of the Angle steel can be customized according to the need, in the production process generally includes hot rolling and cold bending processing. Hot-rolled Angle steel refers to the billet heating to a certain temperature through the rolling road after pressing and forming. Cold bending processing through the machine to form a pretreatment steel plate. According to the shape, it can be divided into equal sides and unequal sides, which can form different stress structures or as connecting structures, which is widely used in various modern construction projects, and is an indispensable and important material in the modern construction industry.

-

ST37 ST52 S235 JRS275 A36 A53 Channel Steel

Product presentation:

Trough steel is a groove long strip steel, which belongs to carbon structural steel for construction and machinery. For the complex section steel, the section shape is a groove shape. The length and size of the channel steel can be customized as required. The production process of trough steel generally includes hot rolling and cold bending processing. Hot rolling tank steel is to heat the billet to a certain temperature. Cold bending processing through the machine to form a pretreatment steel plate. The channel steel is made of hot and cold-rolled steel plate. It has a recess section and is a common material for many steel products.

-

Carbon steel Pipe Fitting A234WPB A420WPL6 ST35.8

Product presentation:

The main products of carbon steel pipe fittings include carbon steel elbow, carbon steel flange, carbon steel tee, carbon steel tee, carbon steel special diameter pipe (large and small head), carbon steel head (pipe cap), etc. The main implementation standards include national standard, American standard, Japanese standard, etc., among which the national standard also includes the Ministry of Chemical Industry standard, Sinopec pipe fittings standard, power pipe fittings standard. Carbon steel pipe fittings are the general term for the connection, control, replacement, shunt, sealing and support components in the pipe system. A pipe fitting is a component that connects a pipe to a pipe. High pressure pipe fittings are suitable for high pressure steam equipment, chemical high temperature and high pressure pipeline, power plant and nuclear power plant pressure vessels, high pressure boiler accessories and other special environments. Pipe fittings are widely used in construction, chemical industry, mining, energy and many other engineering fields. Its important role should not be overlooked.

-

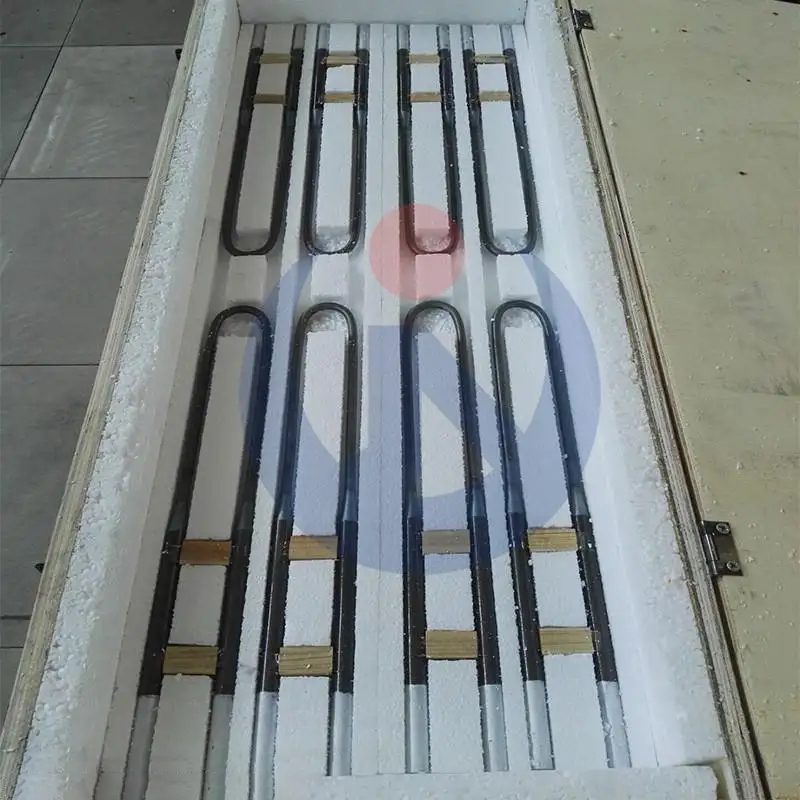

U Tubing Heat Exchanger Tube/ U bend tube/Boiler Tube

Product presentation:

‘U’ bending is done by cold working process.

‘U’ bending is done to the required radius as per customer drawings.

The bend portion and six inch leg is stress relieved by resistance heating.

Inert gas (Argon) is passed through it at the required flow rate to avoid oxidation in ID.

The radius is checked for its OD and wall thinning with the recommended specification.

The physical properties and micro-structure is checked at three different position.

Visual inspection for waviness and cracks is done with Dye Penetrant Test.

Each tube is then hydro tested at the recommended pressure to check for leakage.

Cotton ball test is done to check the ID cleanliness of the tube.

Thereafter pickled, dried, marked and packed.

-

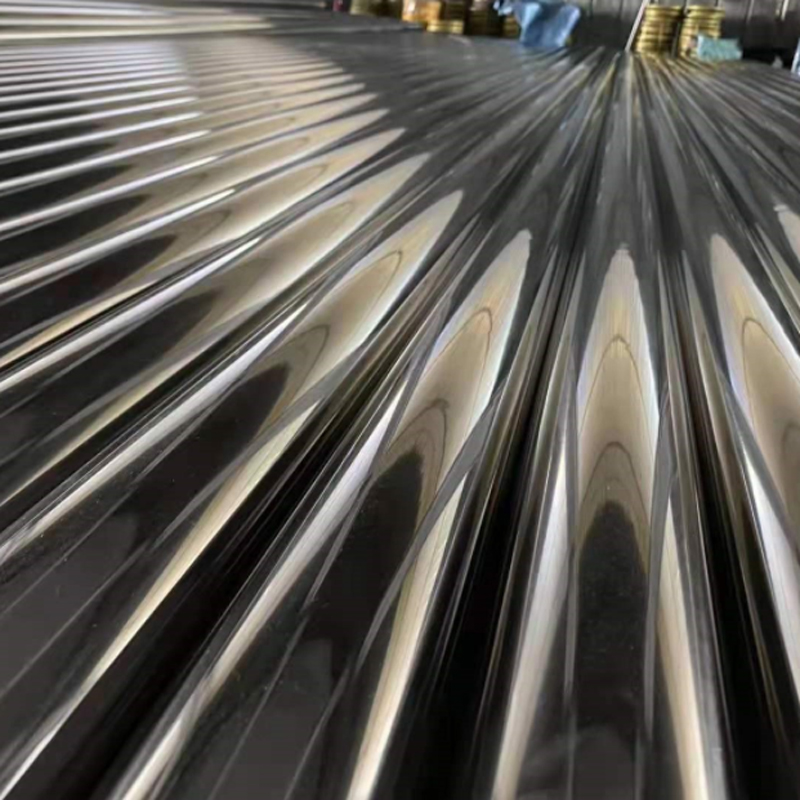

304, 316, 347H, S32205 Stainless Steel Welded Pipe/ERW

Product presentation:

Stainless steel welded pipe, referred to as welding pipe, commonly used steel or steel belt through the unit and mold coil molding after welding made of steel pipe. Welded steel pipe production process is simple, high production efficiency, many varieties and specifications.

According to the use, it is divided into general welded pipe, heat exchanger pipe, condenser pipe, galvanized welded pipe, oxygen welding pipe, wire casing, metric welded pipe, idler pipe, deep well pump pipe, automobile pipe, transformer pipe, electric welding thin wall pipe, electric welding pipe and spiral welded pipe.

-

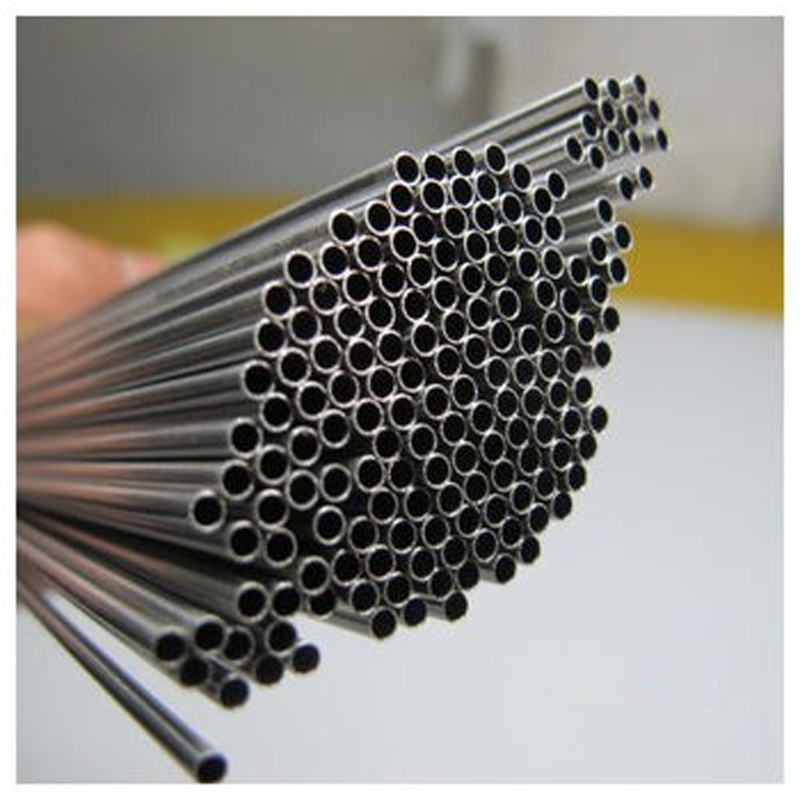

304, 310S, 316L Stainless Seamless Steel Pipe

Product presentation:

Divhot rolled, hot extrusion and cold drawing (rolled) stainless steel pipe according to rolling method.

According to the stainless steel metallographic organization of different stainless steel seamless pipe, marstenitic stainless steel seamless pipe, austenitic stainless steel seamless pipe, austenite-ferric iron stainless steel seamless pipe, etc.

-

A234 WPB SS400 ST35.8 P235GH Carbon Steel Elbow

Product presentation:

In a piping system, the elbow is a pipe fitting that changes the direction of the piping. According to the Angle, there are three most commonly used 45° and 90°180°, in addition to the engineering needs and other abnormal Angle bends such as 60° according to the project. The materials of the elbow include cast iron, stainless steel, alloy steel, forgable cast iron, carbon steel, non-ferrous metals and plastics.

The ways of connecting with the pipe are: direct welding (the most commonly used way) flange connection, hot melt connection, electric melt connection, thread connection and plug connection, etc. According to the production process, it can be divided into: welding elbow, stamping elbow, push elbow, casting elbow, butt welding elbow, etc. Other names: 90-degree bend, right-angle bend, etc.

-

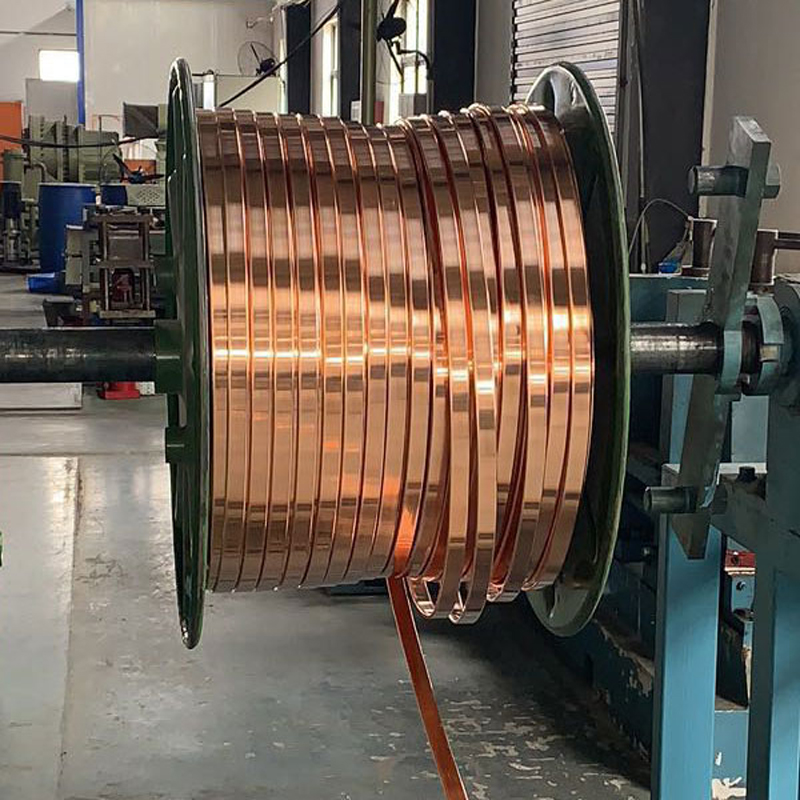

Copper Strips, Copper Sheet, Copper Sheet Coil, Copper Plate

Product presentation:

White copper, is a copper-based alloy with nickel as the main added element, is silvery white, with a metallic luster, hence the name of white copper. Copper and nickel can be dissolved in each other indefinitely, thus forming a continuous solid solution, that is, regardless of the proportion of each other, and constant α -single-phase alloy. When nickel is fused into red copper for more than 16%, the resulting alloy color becomes as white as silver, and the higher the content of nickel, the whiter the color. The content of nickel in white copper is generally 25%.