-

Alloy Steel Pipe Fitting A234WP12 P1 PA22 P5

Product presentation:

Alloy Steel Pipe fittings are a general term of the parts connecting, controlling, changing, diverting, sealing and supporting in the pipe system. A pipe fitting is a part that connects the pipe into a pipe. High pressure pipe fittings are suitable for high pressure steam equipment, chemical high temperature and high pressure pipeline, power plant and nuclear power plant pressure vessels, high pressure boiler accessories and other special environment. Pipe fittings are widely used in many engineering fields such as construction, chemical industry, mining and energy. Its important role should not be ignored.

-

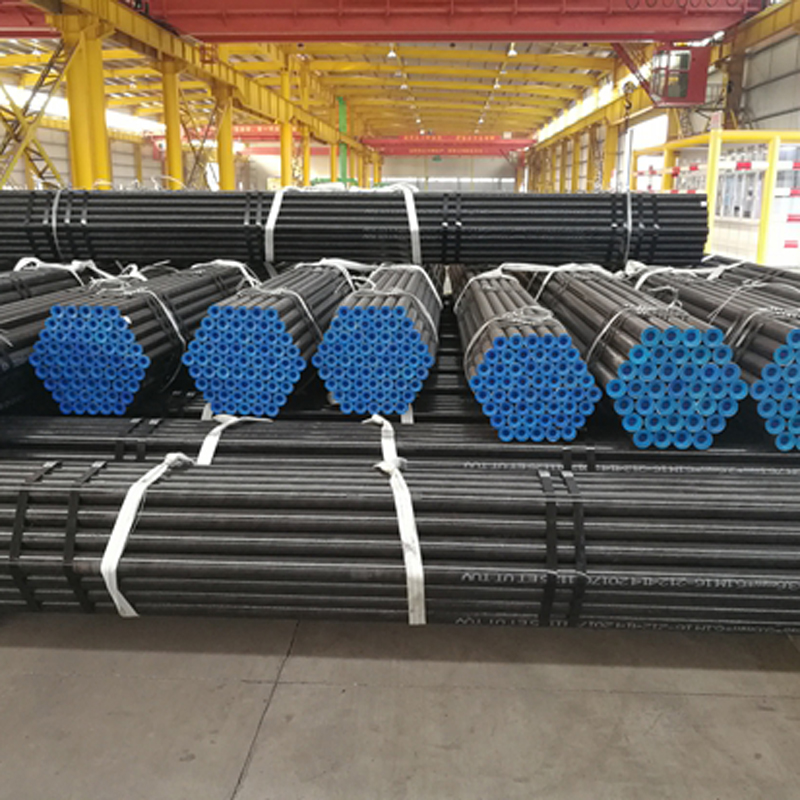

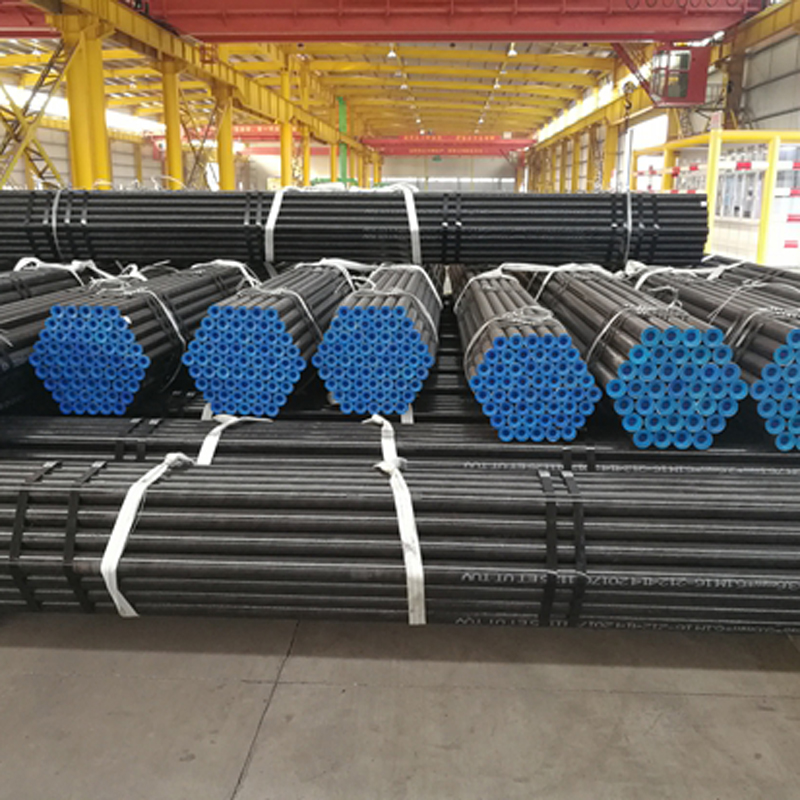

Seamless steel tube for Heat exchanger / Boiler pipe

Product presentation:

Heat Treatment-Is a method that uses heating and cooling to change the physical properties of high-pressure boiler pipes. Heat treatment can improve the microstructure of the high-pressure boiler tube, so that to achieve the required physical requirements. Toughness, hardness, and wear resistance are several of the properties obtained by heat treatment. To obtain these characteristics, use quenching & lt in heat treatment; also called quenching & gt;, tempering, annealing & lt; melting & gt; and surface hardening, etc.

-

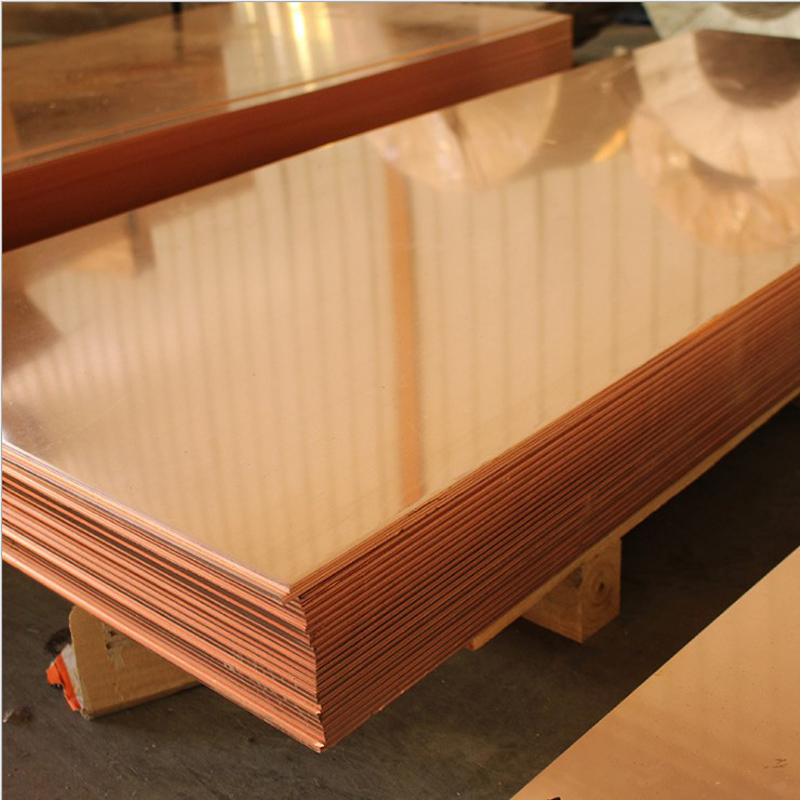

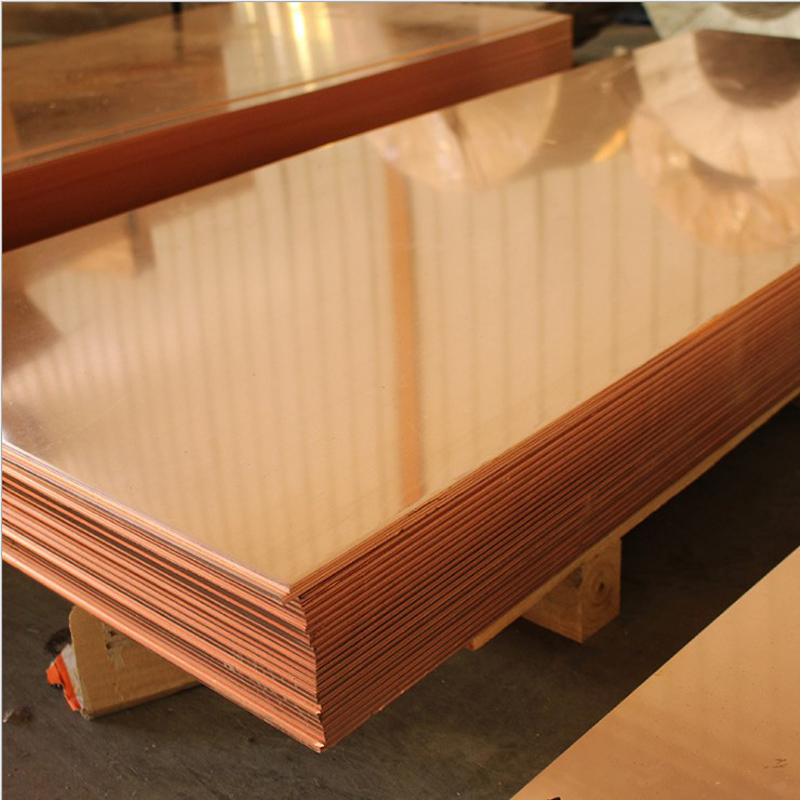

Bronze roll, Copper Sheet, Copper Sheet Coil, Copper Plate

Product presentation:

Pure copper is the copper with the highest amount of copper content, because the main component is copper plus silver, the content is 99.5~99.95%; the main impurity elements: phosphorus, bismuth, antimony, arsenic, iron, nickel, lead, iron, tin, sulfur, zinc, oxygen, etc.; used to make conductive equipment, advanced copper alloy, copper-based alloy.

Aluminum brass can be divided into two categories. One is casting brass aluminum to remove impurities and increase the fluidity, the alloy does not exceed 0.5%; the other is forging brass aluminum to increase corrosion resistance, commonly used as condensing pipe, the general composition range is Al1~6%, Zn 24 ~ 42%, and Cu 55 ~ 71%.

-

Heat Exchanger Finned Tube

Product presentation:

Wing tube heat exchanger is a tubular heat exchanger with wings, which can be composed of one or several fin tubes and can have a shell or shell. It is a new heat exchanger suitable for gas-liquid and steam-liquid that can be customized according to the parameter conditions; fin tube is the basic component of the fin heat exchanger. In order to improve the heat exchange efficiency, fins are usually added on the surface of the heat exchanger tube, so as to increase the outer area of the heat transfer tube, so as to achieve the purpose of improving the heat transfer efficiency.

-

P235GH ST35.8 SA192 Carbon Steel Seamless Pipe / Boiler Tube

Product presentation:

Boiler pipe is a kind of seamless pipe. The manufacturing method is the same as the seamless pipe, but there are strict requirements for the steel type used for manufacturing the steel pipe. According to the temperature of use, it is divided into general boiler pipe and high pressure boiler pipe.

-

T11 T12 T22 T91 T92 Alloy Steel Seamless Pipe

Product presentation:

Alloy seamless steel pipe is a kind of seamless steel pipe, its performance is much higher than the general seamless steel pipe, because this kind of steel pipe contains Cr comparison.

Many, its high temperature resistance, low temperature resistance, corrosion resistance performance is not comparable to other seamless steel pipe, so the alloy pipe in oil, chemical industry, electric power, boiler and other industries are widely used.

Alloy seamless steel pipe contains elements such as silicon, manganese, chromium, nickel, molybdenum, tungsten, vanadium, titanium, niobium, zirconium, cobalt, aluminum, copper, boron, rare earth and so on.

-

Copper Plate, Copper Sheet, Copper Sheet Coil

Product presentation:

Cupronickel:

Copper alloy with nickel as the main added element. Copper nickel binary alloy called ordinary white copper with manganese zinc aluminum and other elements of white copper alloy called complex white copper. Industrial white copper is divided into structure white copper and electrician white copper two categories. Structural white copper is characterized by good mechanical properties and corrosion resistance and beautiful color. This white copper is widely used in the manufacture of precision mechanical glasses accessories, chemical machinery and ship components. Electrician white copper generally has good thermoelectric properties. Manganese white copper with different manganese content is a material used for manufacturing precision electrical instrument rheostor precision resistance strain gauge thermocouple.

-

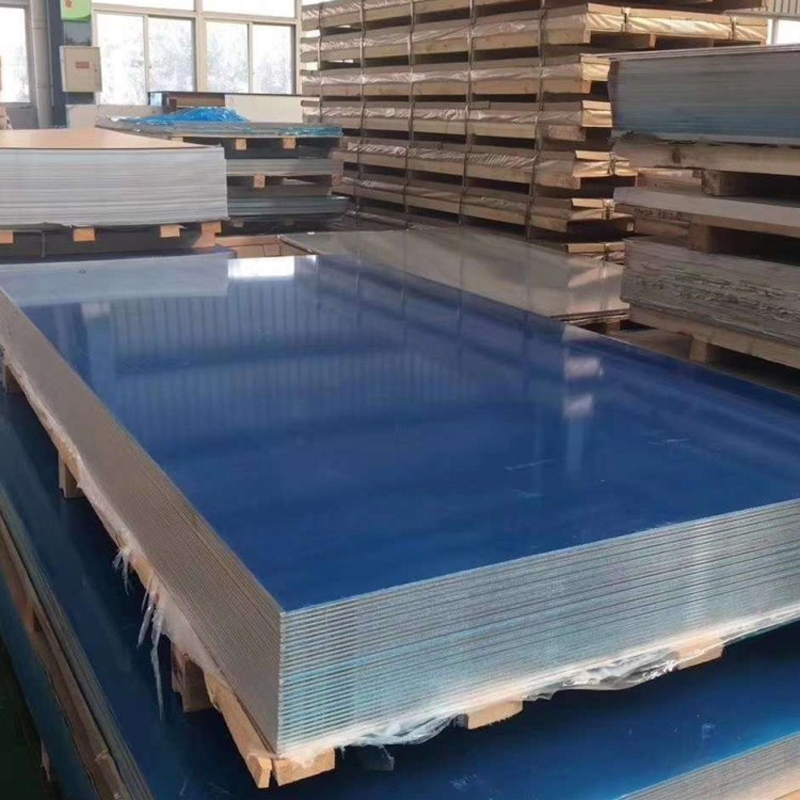

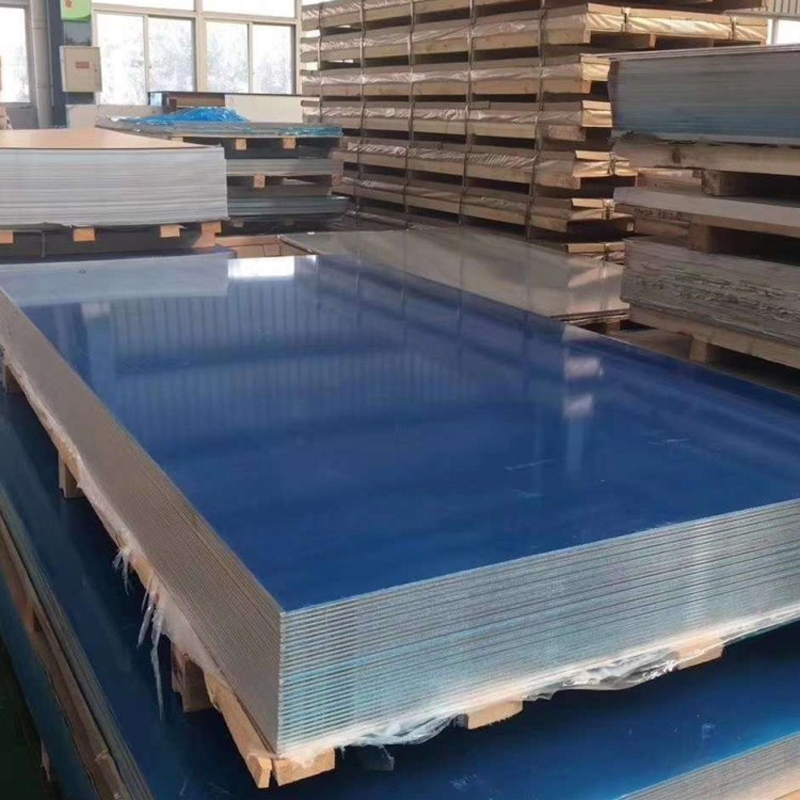

Aluminum Plate/ Aluminum Alloy Plate /7075/5052/6061

Product presentation:

Aluminum alloy plate according to the coating process can be divided into: spraying board products and pre-roller coating board;

According to the paint type can be divided into: polyester, polyurethane, polyamide, modified silicon, fluorocarbon, etc.

Single-layer aluminum plate can be pure aluminum plate, manganese alloy aluminum plate and magnesium alloy aluminum plate.

Forocarbon aluminum board has fluorocarbon spray board and fluorocarbon pre-roll coated aluminum plate.

-

Silicon Steel Coil

Product presentation:

Silicon alloy steel containing 1.0~4.5% silicon and carbon content less than 0.08% is called silicon steel. It has the characteristics of high magnetic conductivity, low coercivity and large resistance coefficient, so the hysteresis loss and eddy current loss are small. Mainly used as magnetic materials in motors, transformers, electrical appliances and electrical instruments. In order to meet the needs of punching and cutting processing when making electrical appliances, a certain plasticity is also required. In order to improve the magnetic susceptibility energy and reduce the hysteresis loss, the lower the harmful impurities content is, the better, and the plate type is flat and the surface quality is good.

-

304, 310S, 316, 347, 2205 Stainless Pipe Fitting

Product presentation:

Stainless Pipe fittings are a general term of the parts connecting, controlling, changing, diverting, sealing and supporting in the pipe system. A pipe fitting is a part that connects the pipe into a pipe. High pressure pipe fittings are suitable for high pressure steam equipment, chemical high temperature and high pressure pipeline, power plant and nuclear power plant pressure vessels, high pressure boiler accessories and other special environment. Pipe fittings are widely used in many engineering fields such as construction, chemical industry, mining and energy. Its important role should not be ignored.

-

Q355, P235GH, 210A1, T1, T11, T12 Round Bar Steel

Product presentation:

Round steel is a solid cylindrical steel, whose diameter can be designed in different sizes according to the production needs. Processing process includes hot rolling, cold drawing, forging and heat treatment and other methods. Among them, hot rolling is the most commonly used process, which can produce round steel with larger diameter. The cold drawing process can produce a smaller diameter and high precision round steel.

-

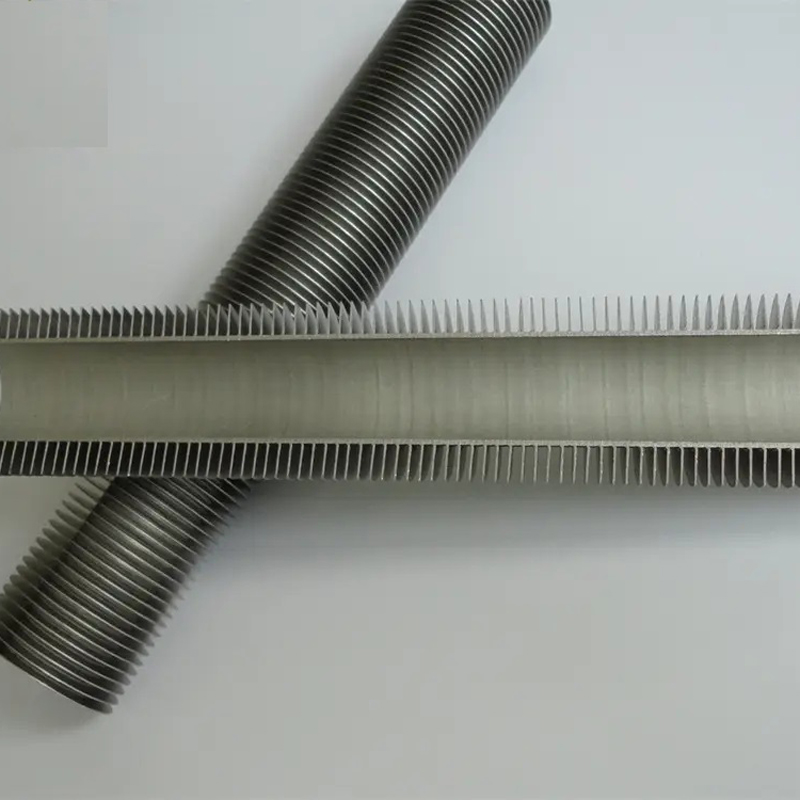

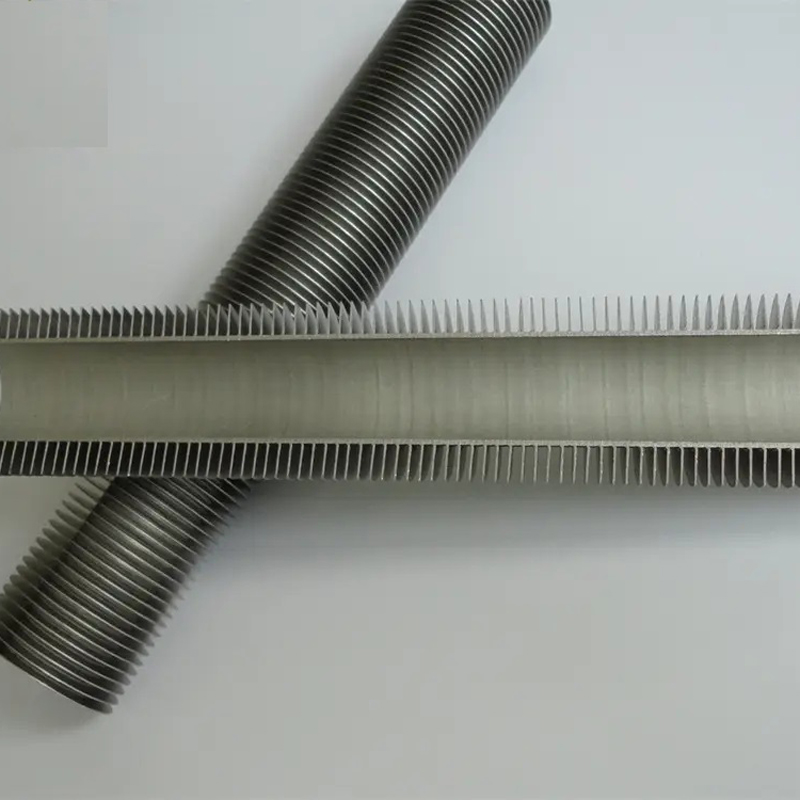

Alloy Stainless Copper Steel Fin Tube

Product presentation:

The trapezoidal section formed by the calendering of the L-shaped fin tube is compatible with the size of the density distribution of heat flow, and the segment is closely combined and the thermal efficiency is high, which eliminates the contact thermal resistance caused by the segment gap.

Operating temperature: 230℃

Characteristics: the use of winding process, high production efficiency, uniform distance, good heat transfer, high wing ratio ratio, the base tube can be protected from air erosion.

Application: mainly used in petrochemical, electric power, paper, tobacco, building heating and other industries of air cooler, air heater and food industry plant protein powder, starch and other spray drying system of air heater.