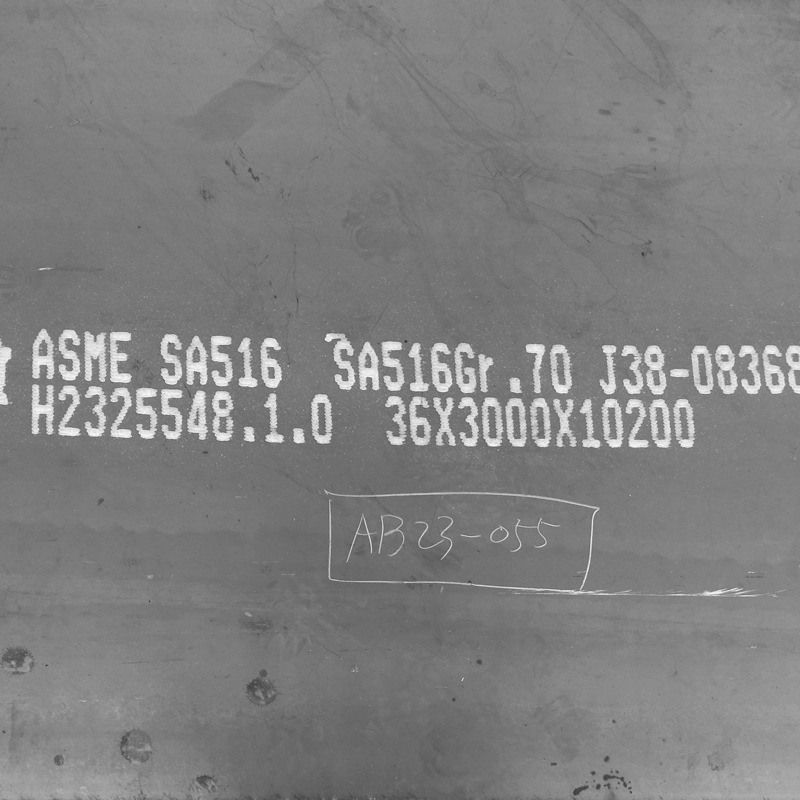

SA516 Gr60 Gr70 SA387Gr22CL2 Container Plate

Delivery status

Quenching: after heating to the phase change point temperature above, the sharp cooling process. Increase the hardness of the material, but reduce the toughness.

Normal heat: after heating to above the phase change temperature, cool normally (in air).

Annealing: after heating to above the phase transition point temperature, then slowly cool down. Eliminate the effect of quenching, eliminate the stress, and eliminate the uniform composition.

Refire: after quenching, then heat to a certain temperature (below the quenching temperature), heat preservation, and then cool. Uniform composition, slightly reduce the hardness, greatly improve the toughness.

It is widely used in petroleum, chemical industry, power station, boiler and other industries, for the production of reactor, heat exchanger, separator, spherical tank, oil and gas tank, liquefied gas tank, nuclear reactor pressure shell, boiler drum, liquefied oil and gas cylinder, hydropower station high pressure water pipe, turbine volute and other equipment and components.

Control rolling is also the control rolling

On the basis of adjusting the chemical composition of steel, by controlling the heating temperature, rolling temperature, deformation system and other process parameters, by controlling the change law of austenite organization and the tissue form of phase change products, so as to achieve the purpose of refining the organization and improving the strength and toughness.

Control rolling regular ignition is to control rolling, rolling temperature, pressure volume, cooling speed, as well as the final rolling temperature and other measures, so that the performance of the steel plate to achieve a good ratio of strength and toughness.

Positive fire, also known as normalization, is a metal heat treatment process to heat the workpiece to Ac 3 or Accm above 30~50℃, heat preservation for a period of time, remove from the furnace in the air or water spray, spray or air cooling. The difference between normal fire and annealing is that the normal fire cooling speed is slightly faster than the annealing cooling speed, so the normal fire tissue is thinner than the annealing tissue, and its mechanical properties are also improved. In addition, the cooling outside the furnace does not occupy the equipment, the productivity is high, so the production is used to replace annealing as far as possible.

The main application scope of the fire is: ① for low carbon steel, the fire after the hardness is slightly higher than annealing, toughness is also good, can be used as cutting processing pretreatment.② Used in medium carbon steel, can be replaced by quality adjustment treatment as the final heat treatment, can also be used as a preparatory treatment before surface quenching by induction heating method.③ For tool steel, bearing steel, carburizing steel, etc., can reduce or inhibit the formation of mesh carbide, so as to get the good organization needed for spherical annealing.④ Used for steel casting, it can refine the casting tissue and improve the cutting performance.⑤ For large forgings, it can be used as the final heat treatment to avoid the large cracking tendency during quenching.⑥ For ductile cast iron, so that the hardness, strength, wear resistance is improved, such as for the manufacture of cars, tractors, diesel engine crankshaft, connecting rod and other important parts.⑦ Total analysis steel bulb annealing before a positive ignition, can eliminate the network secondary carburization, to ensure that all the carburization annealing.

Product Detail

|

Steel Grade: |

SA516 Gr60,SA516Gr65,SA516Gr70,P355GH,P265GH SA387Gr22CL2、SA387Gr22CL2、SA387Gr11CL2;AISI4140,SA285GrCM,SB410,KP42,Q245R,Q345R,SPV355,Q370R,A515Gr70,A516Gr60,A516Gr70,P235GH,P295GH,P355GH,19Mn6,15Mo3,16Mo3,A537CL1,sa622GrC,18MnMoNR,A48CPR,A515Gr65,A516Gr65,SA612M, |

|

Standard: |

DIN EN,ASME,ASTM |

|

Thickness: |

1.0-300mm |

|

Width: |

100-4500mm,or according to customer’s special request |

|

Length: |

1-20meters,or according to customer’s special request |

|

Package: |

Export Standard Package |

|

Application: |

1.Machinery, Pressure vessel industries. 2.Ship building, Engineering construction. 3.Automobile, Bridges, Buildings. 4.Mechanical manufacturing, Pavement slab, ect. |

|

Mill MTC: |

Supplied before shipment |

|

Inspection: |

The Third Party inspection can be accepted,SGS,BV,TUV |

|

Mount Port: |

Any port in China |

|

Trade Term: |

FOB,CIF,CFR,EXW,etc. |

|

Price Term: |

TT or LC at sight |

|

Our Services: |

We can cut and bend steel plate according to customer’s requriement or drawing,packaging according to customers’ request |

Factory Show