Seamless steel tube for Heat exchanger / Boiler pipe

Product presentation

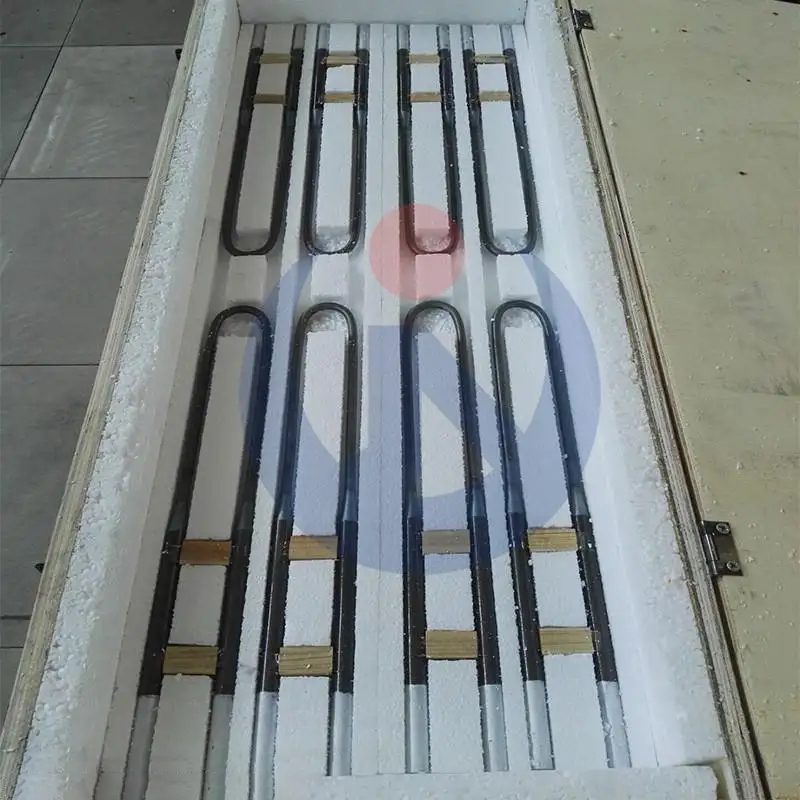

Quenching (Hardening, also known as quenching) -is the high pressure boiler tube evenly heated to the appropriate temperature, and then quickly immersed in water or oil in rapid cooling, or in the air or freezing area cooling, so that the high pressure boiler tube to obtain the required hardness.

The tempering-high pressure boiler pipe will become brittle after quenching. At the same time, the stress caused by quenching and cooling can break the high pressure boiler pipe by light blow. To eliminate the brittleness, the tempering treatment method can be used. Refire is to reheat the high pressure boiler tube to the appropriate temperature or color, and then give the sharp cold. Although the hardness of the high pressure boiler pipe is slightly reduced, it can increase the toughness of the high pressure boiler pipe and reduce its brittleness.

Annealing-annealing is the method to eliminate the internal stress and steel of high pressure boiler pipe. Annealing method is to heat the steel parts to a critical temperature, and then put into the dry ash, lime, asbestos or closed in the furnace, make it slowly cool.

Hardness (Hardness) -is the ability of a material to resist external penetration. The hardness tester is very accurate, which is a common method to test hardness. The most commonly used test method is the Rockwell hardness test Rockwell hardness test machine uses the depth of the diamond rushed into the metal to determine the hardness of the high pressure boiler pipe, the larger the penetration depth, the smaller the hardness. The diamond rushes into the depth of the metal to indicate the correct number from the pointer, which is called the Rockwell hardness number.

Forging-is the hammer to make the metal into a certain shape & lt; molding & gt; method, when the high pressure boiler tube heating to the forging temperature, can be engaged in forging, bending, drawing, molding and other operations. Most high-pressure boiler tubes are easy to forge when heated to bright cherry red.

Britittleness-indicates the nature of high pressure boiler pipe easy to rupture, cast iron is brittle, even fall to the ground will rupture. Britittleness and hardness are closely related, high hardness of 20 # precision steel pipe usually is also brittleness.

ductility- (also known as softness) is the nature of metal permanent deformation by external force without fragmentation, ductility of high pressure boiler pipe can be pulled into thin lines.

Elastic-is a property of the high pressure boiler tube deformed by external force, when the external force is eliminated. Spring steel is a very elastic material.

Hardness-is a metal resistance to external puncture or cutting can increase the high pressure boiler tube hardness common method is quenching.

Performance- -also known as malleability, is another representation of metal ductility or softness. Exhibition is a property of metal receiving hammer forging or rolling.

Toughness is the ability of high pressure boiler pipe to withstand vibration or impact. The toughness is just the opposite of the brittleness.

In the production process of seamless steel pipe for boiler, heat treatment is the key process. Heat treatment has an important impact on the internal quality and surface quality of seamless steel pipe, which is particularly important for the production of alloy seamless steel pipe.

Our company adopts non-oxidation heat treatment, the production of steel pipes with stable metallographic organization and good internal and external surface quality, using eddy current and ultrasonic automatic flaw detection, steel pipe one by one for eddy current flaw detection and ultrasonic flaw detection. With ultrasonic thickness measurement and oblique flaw detection functions, it can effectively detect the layered defects in the steel pipe.

Product Detail

|

Steel Grade: |

106B,210A1,210C,P9,P11,T1,T11,T2,T5,T12,T22,T23,T91,T92,P235GH,13CrMo4-5,15Mo3,10CrMo9-10, ST35.8,ST45.8,STB340,STBA 12-2,API5L,5CT,ND-Steel Pipe |

|

Standard: |

ASME/ASTM SA/A53/513/106/209/210/213/335/178/179/519 ASME/ASTM SA/A213,A312,A269,A778,A789, DIN 17456, DIN17457,DIN 17459,DIN17175,EN10216,BS3605,BS3059 |

|

Specification: |

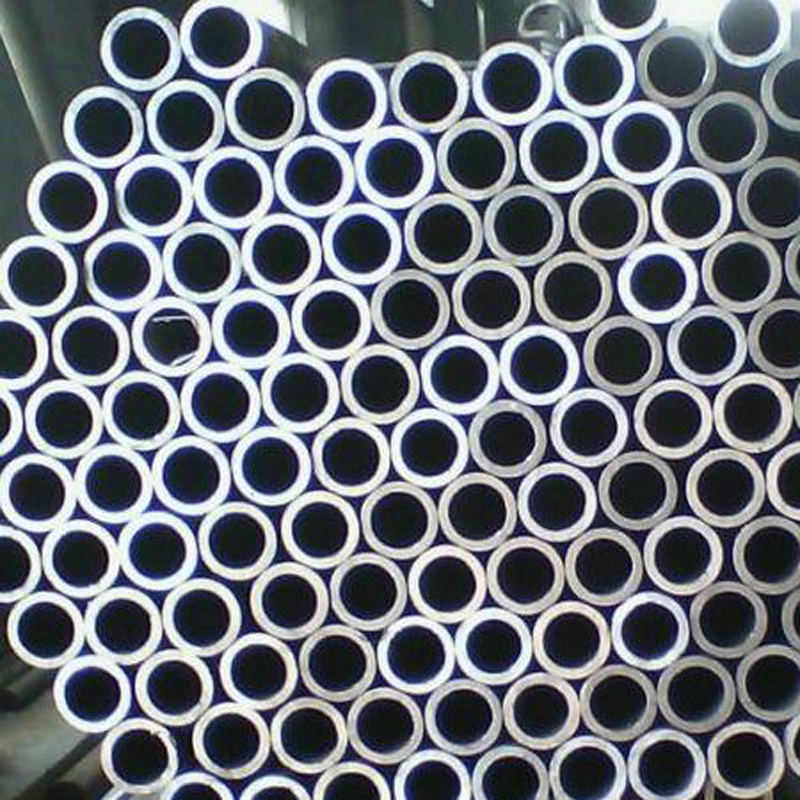

Outdiameter 10~508mm |

|

Wt: |

1.0-30mm,or according to customer’s special request |

|

Length: |

2-20meters,or according to customer’s special request |

|

Package: |

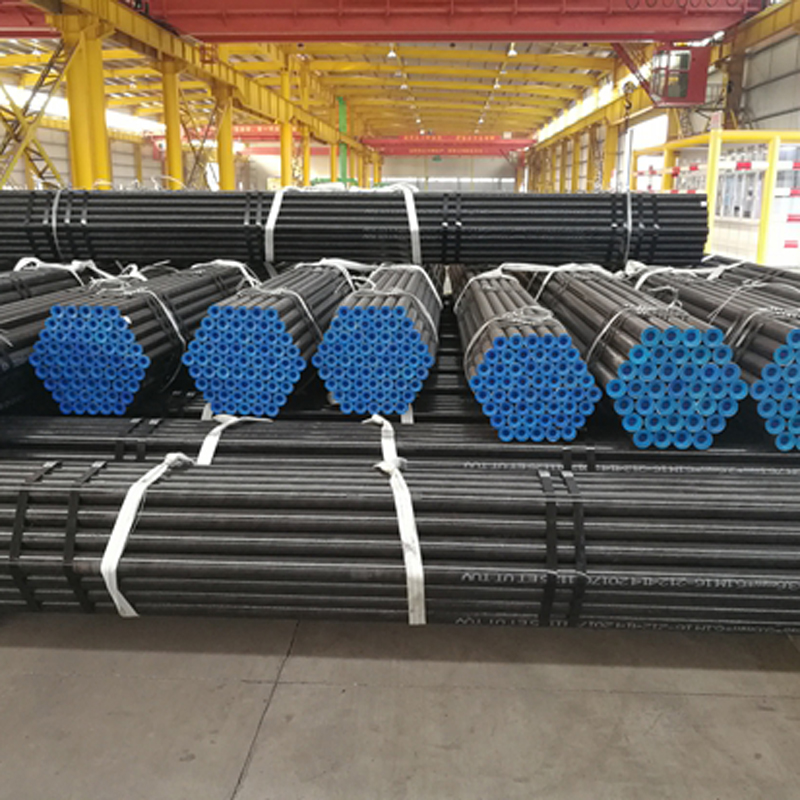

Export Standard Package |

|

Typies of tube: |

Boiler tube,precision tube,mechanical tubing,cylinder tube,line pipes,etc |

|

Mill MTC: |

Supplied before shipment |

|

Inspection: |

The Third Party inspection can be accepted,SGS,BV,TUV |

|

Mount port: |

Any port in China |

|

Trade Term: |

FOB,CIF,CFR,EXW,etc. |

|

Price Term: |

TT or LC at sight |

|

Our services: |

We can customized according to customer’s requriement or drawing ,packaging according to customers’ request |

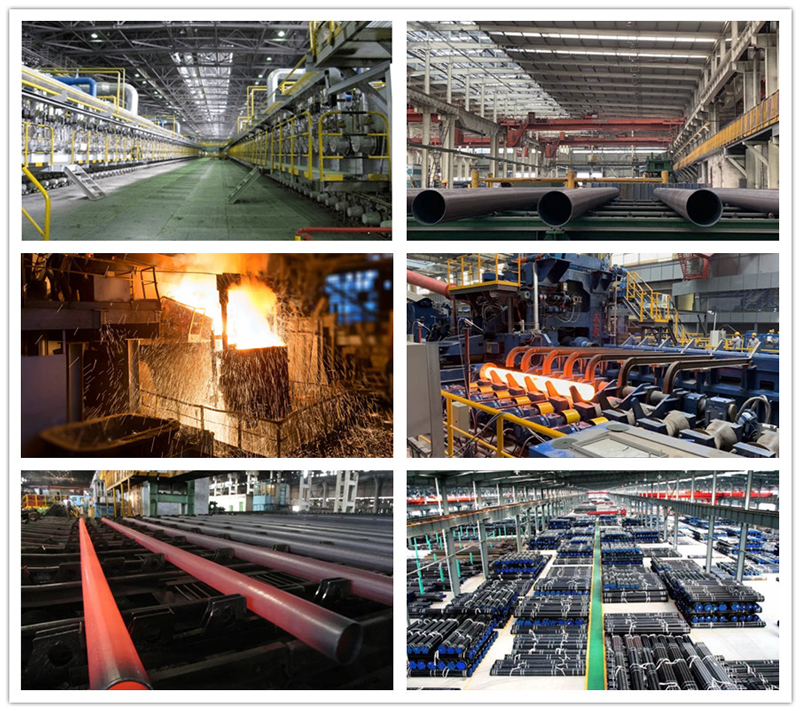

Factory Show