-

SA588 SA387 Alloy Steel Plate

Product presentation:

According to the content of alloy elements is divided into:

low alloy steel (the total amount of alloy elements is less than 5%),

Medium alloy steel (5% -10% of total alloy elements)

High alloy steel (total alloy element is higher than 10%).

According to the alloy element composition into:

Chromium steel (Cr-Fe-C)

Chromium-nickel steel (Cr-Ni-Fe-C)

Manganese Steel (Mn-Fe-C)

Silicon-manganese steel (Si-Mn-Fe-C)

-

Wear-Resisting Plate, Weathering Resistant Plate

Product presentation:

The wear-resistant steel plate is composed of two parts: the low-carbon steel plate and the alloy wear-resistant layer. The alloy wear-resistant layer is generally 1 / 3~1 / 2 of the total thickness. When working, the matrix provides the comprehensive performance such as strength, toughness and plasticity, and the alloy wear-resistant layer provides the wear-resistance to meet the requirements of the specified working conditions.

The alloy wear-resistant layer is mainly chromium alloy, and manganese, molybdenum, niobium, nickel and other alloy components are also added. The carbide in the metallographic tissue is distributed in the fiber shape, and the fiber direction is perpendicular to the surface. The microhardness of carbide can reach above HV1700-2000, and the surface hardness can reach HRC 58-62. Alloy carbide has a strong stability at high temperature, maintain a high hardness, but also has a good antioxidant properties, within 500℃ completely normal use.

-

SA516 Gr60 Gr70 SA387Gr22CL2 Container Plate

Product presentation:

Container plate is mainly used for pressure vessel use

-

S235JR S275JR S355JR Carbon Steel Plate

Product presentation:

Steel plates are divided into hot and cold rolled plates.

According to steel types, there are ordinary steel, high quality steel, alloy steel, spring steel, stainless steel, tool steel, heat resistant steel, bearing steel, silicon steel and industrial pure iron sheet.

High quality carbon structural steel can be divided into three categories according to different carbon content: low carbon steel (C 0.25%), medium carbon steel (C is 0.25-0.6%) and high carbon steel (C & gt; 0.6%).

High quality carbon structural steel is divided into normal manganese (0.25% -0.8%) and higher manganese (0.70% -1.20%), the latter has good mechanical properties and processing properties.

-

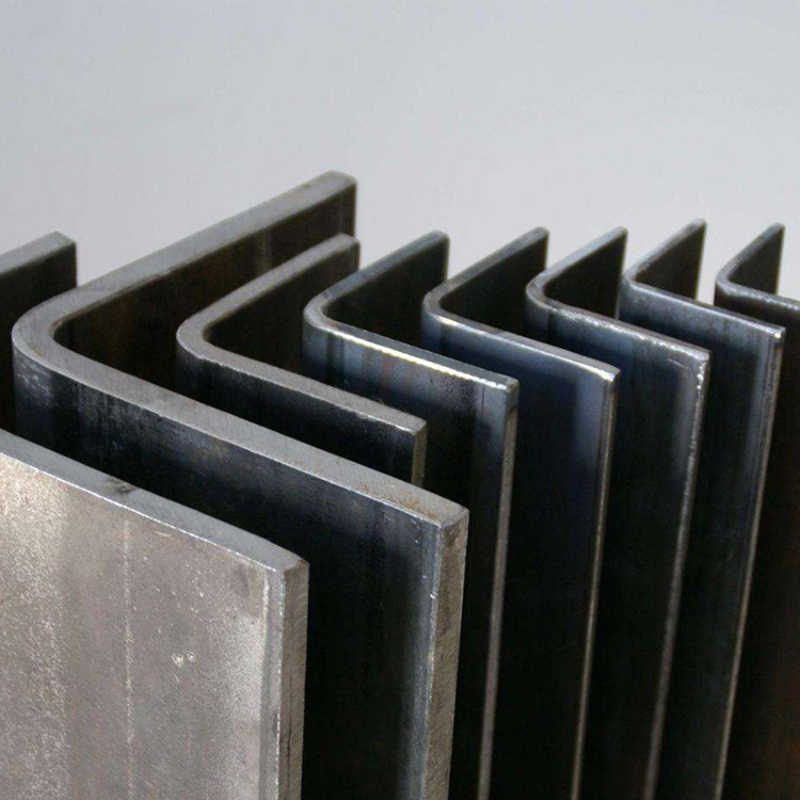

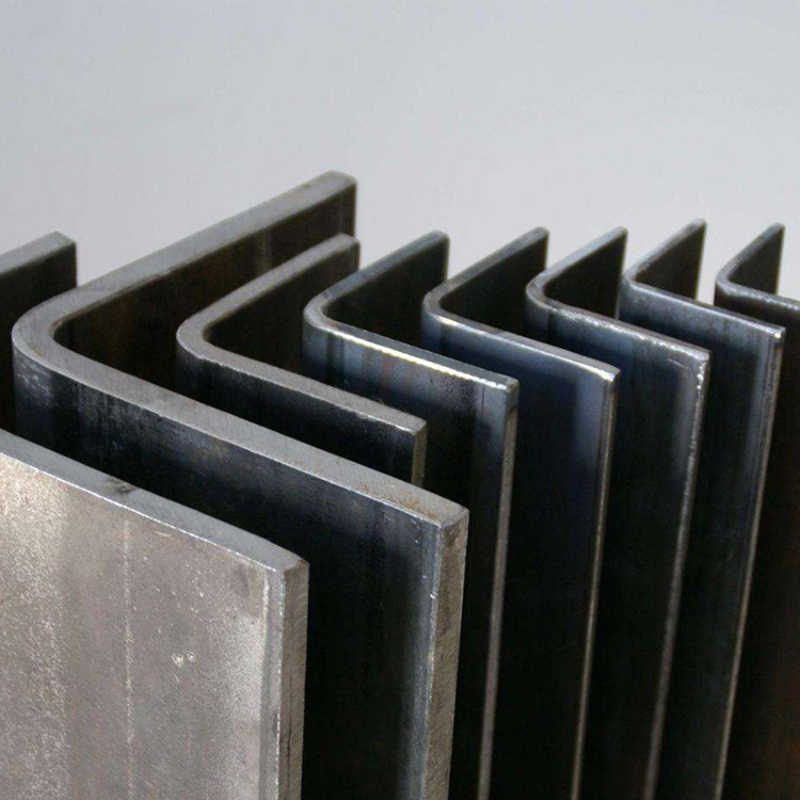

ST37 ST52 S235 JRS275 A36 A53 Angle Steel

Product presentation:

Angle steel is a L-shaped steel, usually made of hot rolled or cold bending. The length and size of the angle steel can be customized as needed.

The production process of Angle steel generally includes hot rolling and cold bending processing. Hot rolled Angle steel is to heat the billet to a certain temperature through the roller road after pressing molding, the production efficiency is high, but the cost is relatively high. The cold bending processing is through the machine to form the pretreatment steel plate, the cost is low but the production efficiency is relatively low.

-

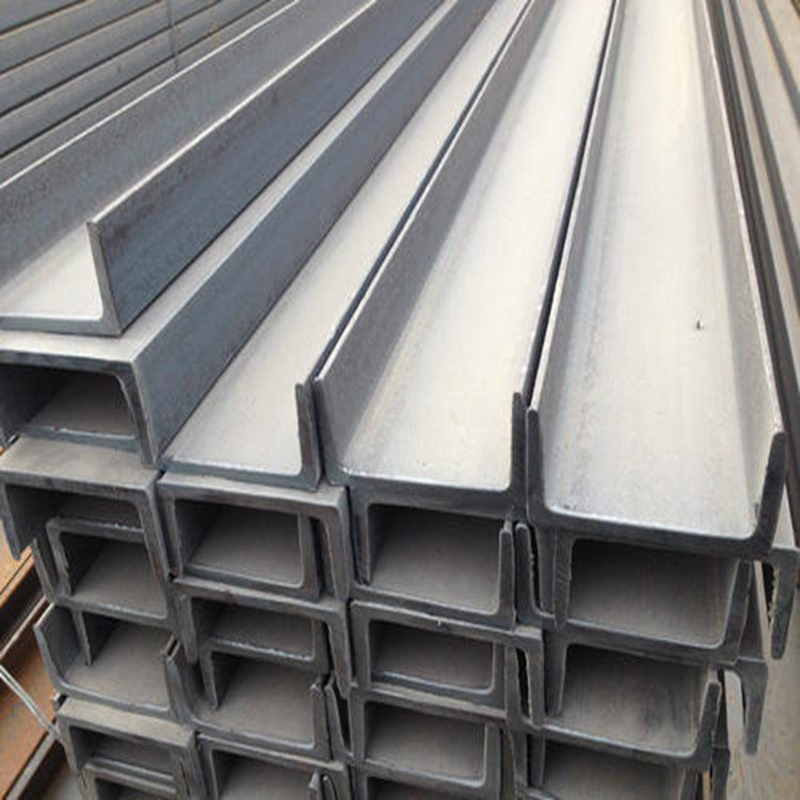

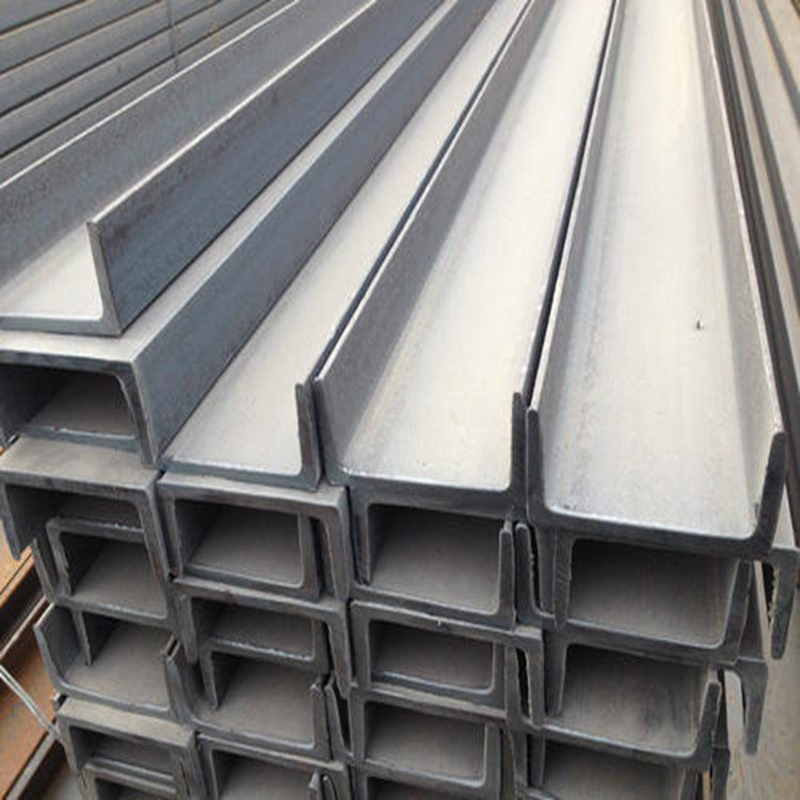

304, 310S, 316, 347, 2205 Stainless Channel Steel

Product presentation:

Stainless steel groove steel is a long section of groove shaped steel, belongs to the construction and mechanical carbon structure steel, is a complex section of the section steel, its section shape is groove shape. The length and size of the channel steel can be customized as needed.

The production process of stainless steel trough steel generally includes two ways: hot rolling and cold bending processing. Hot rolling groove Angle steel is to heat the billet to a certain temperature through the roller channel for pressing molding. The cold bending processing is through the machine to form the pretreatment steel plate.

Stainless steel trough steel is made of hot rolled and cold rolled steel plate coil through bending and forming. It has a groove section and is a common material in many steel products. It is widely used in construction, machinery manufacturing, petrochemical, industry and transportation fields.

-

304, 310S, 316, 347, 2205 Stainless Round Bar Steel

Product presentation:

Stainless Round steel is a solid cylindrical steel, whose diameter can be designed in different sizes according to the production needs. Processing process includes hot rolling, cold drawing, forging and heat treatment and other methods. Among them, hot rolling is the most commonly used process, which can produce round steel with larger diameter. The cold drawing process can produce a smaller diameter and high precision round steel.

-

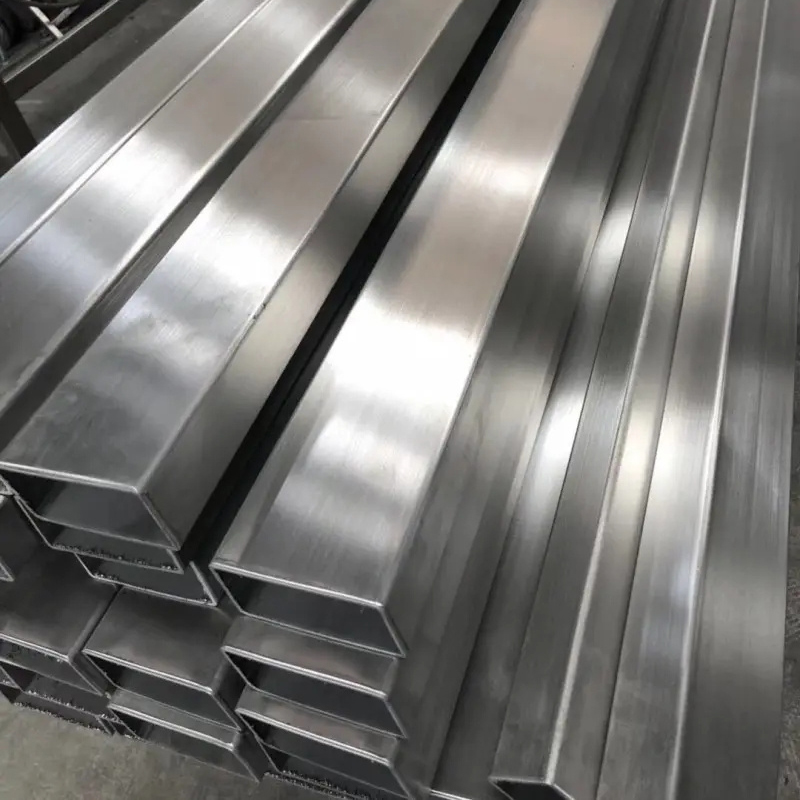

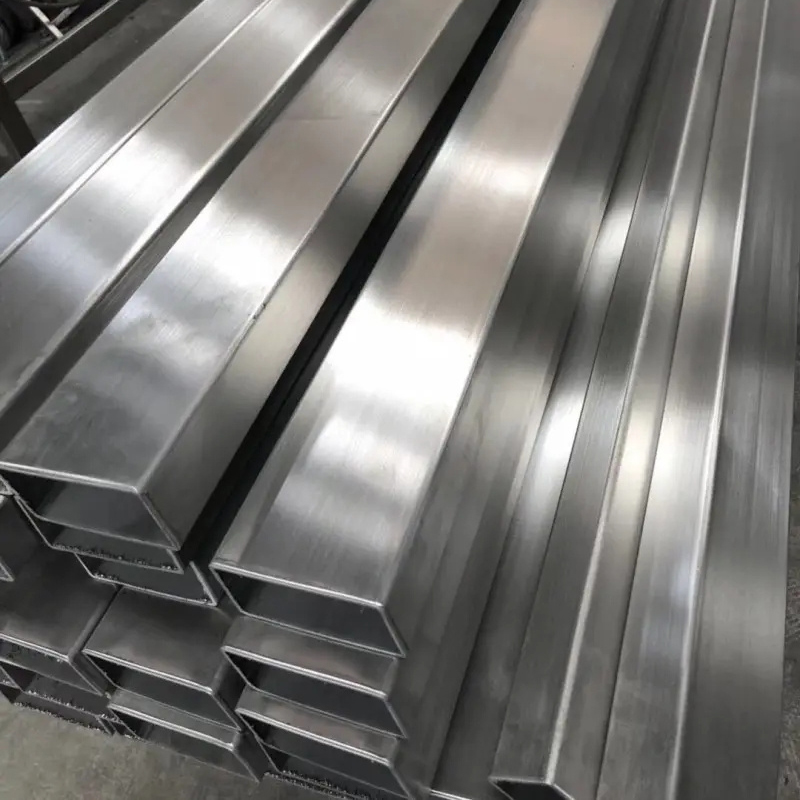

St52 A178 A53/304 316 347 Welded Square/Rectangular Tube

Product presentation:

Square pipe is a hollow square cross section light thin-wall steel pipe, also known as steel refrigeration bending profile. It is a hot rolled or cold rolled strip or coil as the base material by cold bending processing and then made of high frequency welding square section shape size of the steel. Except for the wall thickness and thickening, the corner size and the smoothness of the side all reach or even exceed the level of the resistance welded cold forming square pipe. Comprehensive mechanical properties, weldability, cold and hot machining properties and corrosion resistance are good, with good low temperature toughness.

Pipe use of construction, mechanical manufacturing, steel construction projects, shipbuilding, solar power support, steel structure engineering, electric power engineering, power plant, agriculture and chemical machinery, glass curtain wall, car chassis, airport, boiler construction, highway railings, housing construction, pressure vessels, oil storage tanks, Bridges, power station equipment, lifting transportation machinery and other higher load of welding structure, etc.

-

St37 St52 A214 A178 A53 A423 Galvanized Welded Pipe, ERW

Product presentation:

Hot-dip galvanized pipe is to make the molten metal and iron matrix reaction and produce an alloy layer, so that the matrix and the coating layer are combined. Hot galvanizing is the steel pipe first, in order to remove the iron oxide on the surface of the steel pipe, after pickling, through the ammonium chloride or zinc chloride solution or ammonium chloride and zinc chloride mixed solution tank, and then sent into the hot dip plating tank. Hot-dip galvanizing has the advantages of uniform coating, strong adhesion and long service life. Complex physical and chemical reaction occurs with the molten plating solution of the hot-dip galvanized steel pipe, forming a corrosion-resistant and tight zinc-one iron alloy layer. Alloy layer is integrated with pure zinc layer and steel tube matrix, so its corrosion resistance is strong.

-

API 5L 3PE Q345 St37 St52 Welded Pipe, ERW, Spiral Welded Pipe

Product presentation:

The billet used for welding steel pipe is steel plate or strip steel, due to its different welding process, it is divided into furnace welding pipe, electric welding (resistance welding) pipe and automatic arc welding pipe. Because of its different welding forms, it is divided into straight seam welded pipes and spiral welded pipes. Because of its end shape is divided into circular welded pipe and different type (square, flat, etc.) welded pipe.

-

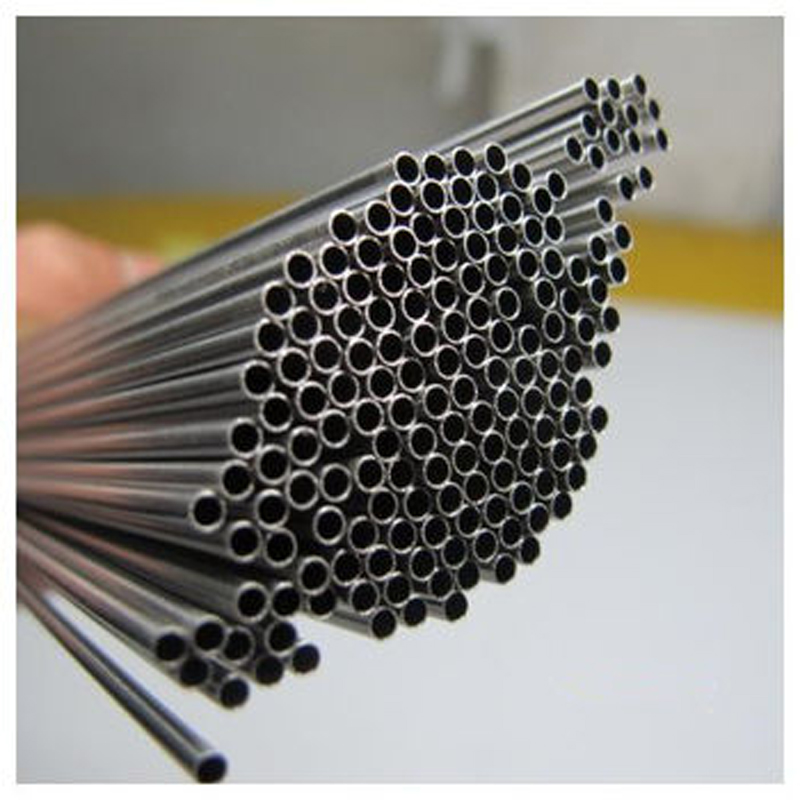

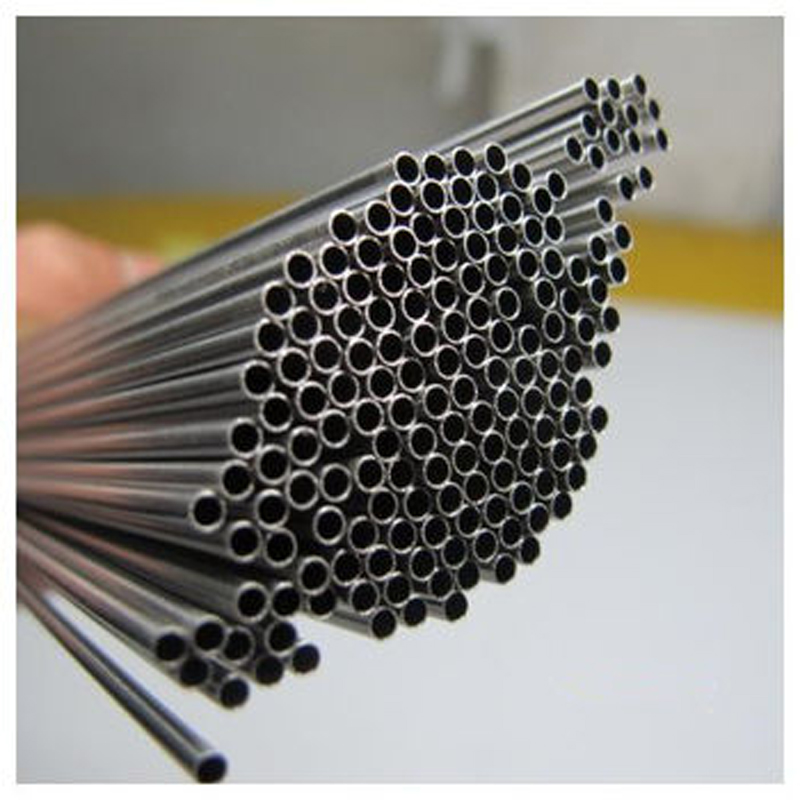

316L 347H S32205 Stainless Seamless Steel Pipe

Product presentation:

Classification of Stainless steel pipe: stainless steel seamless steel pipe and stainless steel welded steel pipe (with seams) two basic categories. According to the outer diameter shape of the steel pipe can be divided into round pipe and special-shaped pipe, widely used is the circular steel pipe, but there are also some square, rectangular, semicircular, hexagonal, equilateral triangle, octagonal and other special-shaped steel pipe.

Stainless steel seamless pipe is made of steel ingot or solid pipe billet through perforation, and then by hot rolled, cold rolled or cold dial made. -

201, 304, 347H, S32205 Stainless Steel Welded Pipe/ ERW

Product presentation:

Classification of Stainless steel pipe: stainless steel seamless steel pipe and stainless steel welded steel pipe (with seams) two basic categories. According to the outer diameter shape of the steel pipe can be divided into round pipe and special-shaped pipe, widely used is the circular steel pipe, but there are also some square, rectangular, semicircular, hexagonal, equilateral triangle, octagonal and other special-shaped steel pipe.

According to the use, it is divided into general welded pipe, heat exchanger pipe, condenser pipe, galvanized welded pipe, oxygen welding pipe, wire casing, metric welded pipe, idler pipe, deep well pump pipe, automobile pipe, transformer pipe, electric welding thin wall pipe, electric welding pipe and spiral welded pipe.