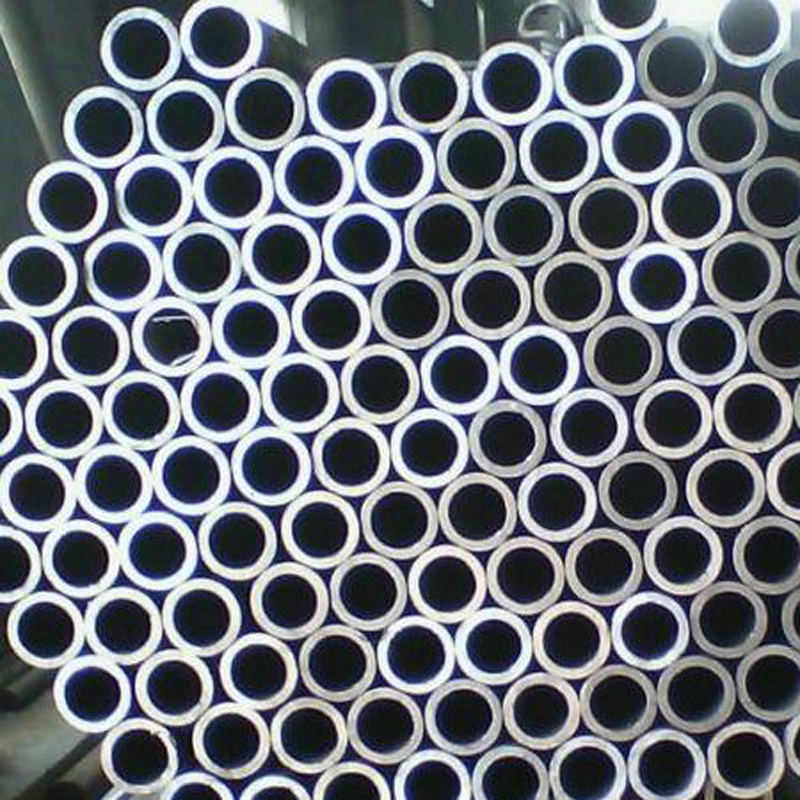

T11 T12 T22 T91 T92 Alloy Steel Seamless Pipe

manufacturing process

Hot rolling (extruded seamless steel pipe): round pipe billet heating perforation three roll inclined rolling, continuous rolling or extruded strip diameter (or reduced diameter) cooling billet straightening hydraulic test (or flaw) mark for storage.

Cold pull pipe (rolled) seamless steel pipe: round tube billet heated, perforated head, annealing, pickling and coated oil (copper plating) multi-channel cold pull pipe (cold rolled) billet pipe heat treatment straightening hydraulic test (flaw detection) mark into storage.

In the production process of seamless steel pipe for boiler, heat treatment is the key process. Heat treatment has an important impact on the internal quality and surface quality of seamless steel pipe, which is particularly important for the production of alloy seamless steel pipe.

Our company adopts non-oxidation heat treatment, the production of steel pipes with stable metallographic organization and good internal and external surface quality, using eddy current and ultrasonic automatic flaw detection, steel pipe one by one for eddy current flaw detection and ultrasonic flaw detection. With ultrasonic thickness measurement and oblique flaw detection functions, it can effectively detect the layered defects in the steel pipe.

Quality inspection method of seamless steel pipe

1. Chemical composition analysis: chemical analysis method, instrument analysis (infrared C-S instrument, direct reading spectrometer, zcP, etc.).

2. Surface quality inspection of steel pipe: 100%

A. Ultrasonic detection UT:

B. ET: (electromagnetic induction)

C. MT and leakage detection:

Magnetic flaw detection, suitable for the detection of surface and near-surface defects of ferromagnetic materials.

D. Electromagnetic ultrasonic flaw detection:

No coupling medium is needed, which can be applied to high temperature and high speed, rough and dry steel pipe surface flaw detection.

E. liquid penetrating test:

Fluorescence, coloring, and detecting of steel pipe surface defects.

3. Physical and chemical performance inspection of steel pipe:

4. Process performance inspection of steel pipe:

Product Detail

|

Steel Grade: |

106B,210A1,210C,P9,P11,T1,T11,T2,T5,T12,T22,T23,T91,T92,P235GH,13CrMo4-5,15Mo3,10CrMo9-10, ST35.8,ST45.8,STB340,STBA 12-2,API5L,5CT,ND-Steel Pipe |

|

Standard: |

ASME/ASTM SA/A53/513/106/209/210/213/335/178/179/519 ASME/ASTM SA/A213,A312,A269,A778,A789, DIN 17456, DIN17457,DIN 17459,DIN17175,EN10216,BS3605,BS3059 |

|

Specification: |

Outdiameter 10~508mm |

|

Wt: |

1.0-30mm,or according to customer’s special request |

|

Length: |

2-20meters,or according to customer’s special request |

|

Package: |

Export Standard Package |

|

Typies of tube: |

Boiler tube,precision tube,mechanical tubing,cylinder tube,line pipes,etc |

|

Mill MTC: |

Supplied before shipment |

|

Inspection: |

The Third Party inspection can be accepted,SGS,BV,TUV |

|

Mount port: |

Any port in China |

|

Trade Term: |

FOB,CIF,CFR,EXW,etc. |

|

Price Term: |

TT or LC at sight |

|

Our services: |

We can customized according to customer’s requriement or drawing ,packaging according to customers’ request |

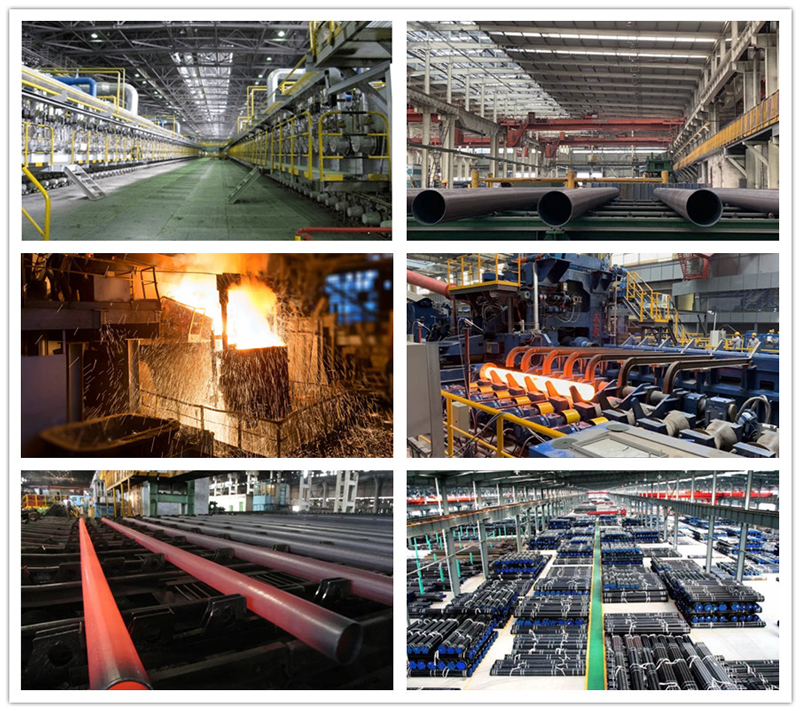

Factory Show