-

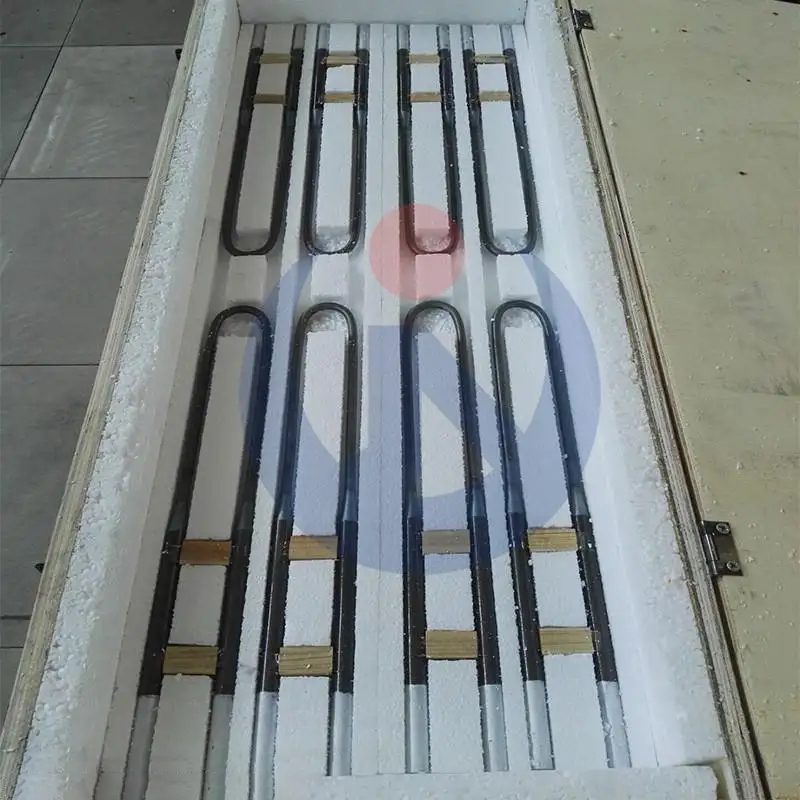

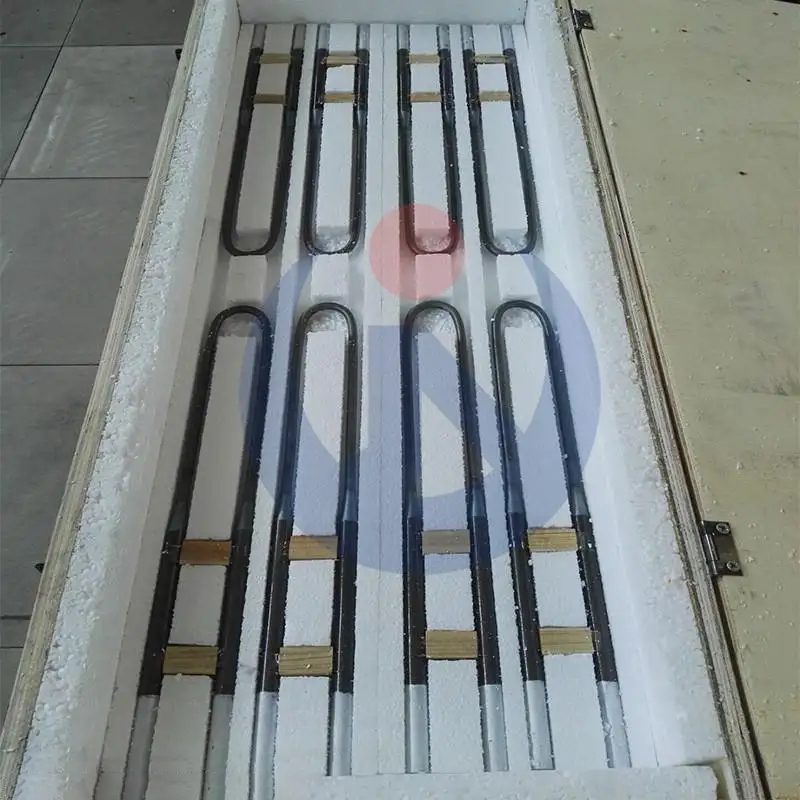

U Tubing Heat Exchanger Tube/ U bend tube/Boiler Tube

Product presentation:

‘U’ bending is done by cold working process.

‘U’ bending is done to the required radius as per customer drawings.

The bend portion and six inch leg is stress relieved by resistance heating.

Inert gas (Argon) is passed through it at the required flow rate to avoid oxidation in ID.

The radius is checked for its OD and wall thinning with the recommended specification.

The physical properties and micro-structure is checked at three different position.

Visual inspection for waviness and cracks is done with Dye Penetrant Test.

Each tube is then hydro tested at the recommended pressure to check for leakage.

Cotton ball test is done to check the ID cleanliness of the tube.

Thereafter pickled, dried, marked and packed.

-

Stainless Steel/ Nickle Alloy U Bend Tubes

Product presentation:

The U tube is usually used to exchange heat in process fluids with large radiators. The fluid is pumped out along a pipe, then through a U-junction, and back along a pipe parallel to the inflow line. Heat is transferred through the wall of the tube to the wrapping material. This design is used for industrial applications, where many U tubes can be poured into oil containers containing high heat capacity.